At Tender Wire Mesh, quality is the foundation of everything we do. With over 30 years of experience in wire mesh manufacturing, we are committed to delivering products that meet the highest industry standards. To ensure precision, durability, and consistency, we have established a comprehensive quality control system that spans the entire production process—from raw material inspection to final product testing.

Our in-house quality lab is equipped with advanced testing equipment, including:

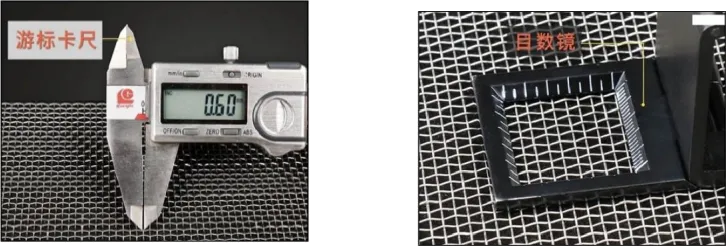

Conduct rigorous measurements of raw materials and finished products using professional measuring instruments

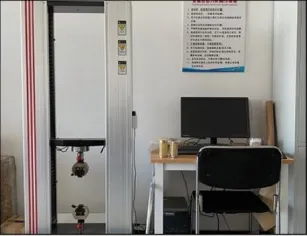

Used to measure the strength and elongation of wire materials, ensuring they meet specified mechanical performance standards.

Performs precise analysis of chemical composition in metals, verifying material grade and alloy accuracy before production begins.

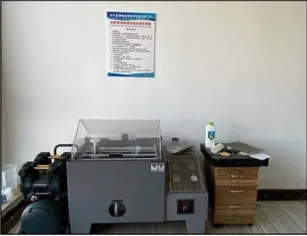

Simulates harsh environmental conditions to evaluate the corrosion resistance of wire mesh surfaces, particularly important for stainless steel and coated products.

Provides high-resolution dimensional inspection of mesh aperture, wire diameter, and overall uniformity to guarantee precision in mesh structure.

By combining rigorous inspection protocols with cutting-edge testing tools, we maintain tight tolerances and reliable performance in every batch of wire mesh we produce. Our commitment to quality ensures that our products consistently meet the demands of industries such as filtration, construction, mining, and energy.

At Tender Wire Mesh, quality is not just a promise—it’s a process, built into every step of production.

Wählen Sie das gewünschte Produkt aus

Folgen Sie unserem Blog