-

Vantagens Característica

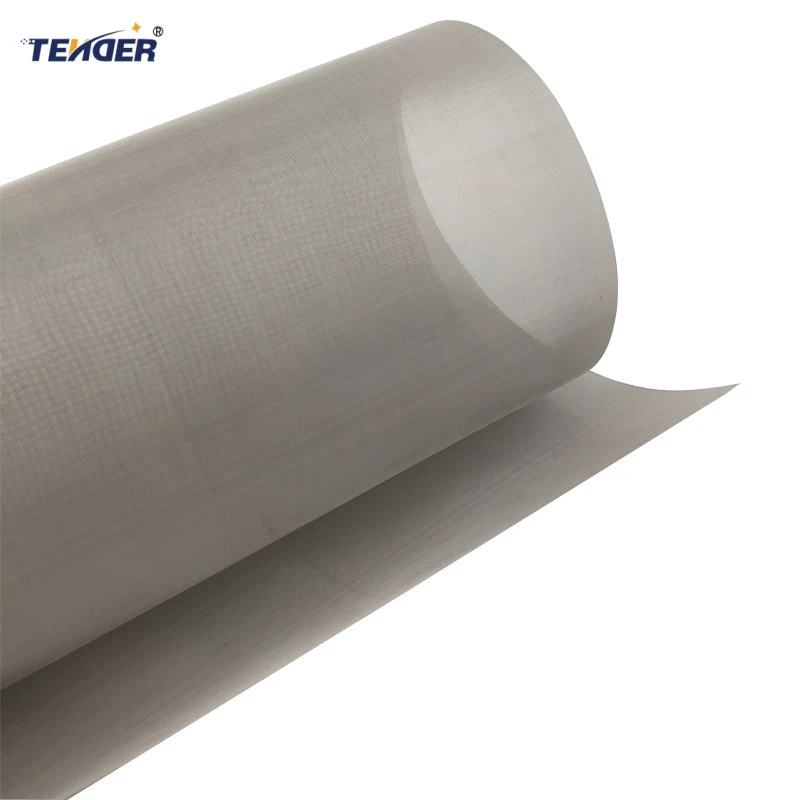

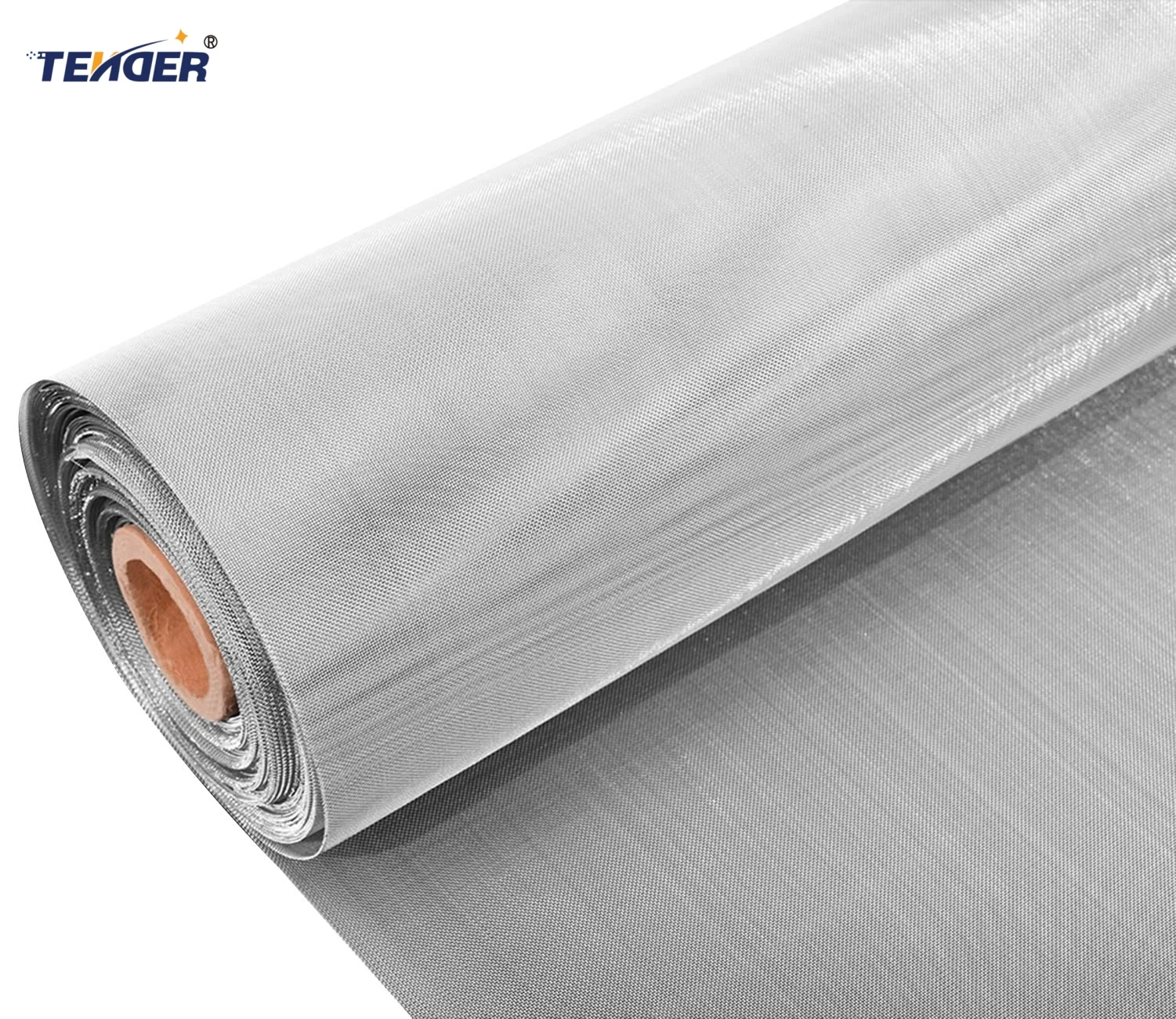

Nickel woven wire mesh or low-alloy nickel woven wire mesh is useful in chemical processing because of its resistance to various chemicals including acid, alkali. It is also useful in the electronics due to its high electrical conductivity. The Nickel wire can be also used in the heat exchange due to its thermal conductivity and ductility.

-

Especificações comuns

Material: nickel 200, nickel 205, nickel 270, N2, N4, N6, N8.

Weaving type: plain weave, twill weave and dutch weave.

Wire diameter: 0.0018" - 0.0280".

Mesh size: 8 mesh - 200 mesh.

Width: 36", 48".

Length: customized.

Tipo

Ni + Co

Cu

Si

Mn

C

Mg

S

Fe

Impurity Sum

Min.

Max.

N2

99.98

0.001

0.003

0.002

0.005

0.003

0.001

0.007

0.02

N4

99.9

0.015

0.03

0.002

0.01

0.01

0.001

0.04

0.1

N6

99.5

0.03

0.1

0.05

0.1

0.1

0.005

0.1

0.5

N8

99

0.15

0.15

0.2

0.2

0.1

0.015

0.3

1

Mesh count

Wire Diameter (in.)

Type Weave

Width Opening (in.)

Open Area (%)

8 × 8

0.028

Plain

0.097

60.2

10 × 10

0.02

Plain

0.08

64%

12 × 12

0.014

Plain

0.0693

69.2

16 × 16

0.012

Plain

0.0505

65.3

16 × 16

0.014

Plain

0.0485

60.2

20 × 20

0.0045

Plain

0.0455

82.8

20 × 20

0.007

Plain

0.043

74

20 × 20

0.014

Plain

0.036

51.8

25 × 25

0.006

Plain

0.019

57.8

26 × 26

0.01

Plain

0.0285

54.8

30 × 30

0.013

Plain

0.0203

37.2

40 × 40

0.006

Plain

0.019

57.8

40 × 40

0.01

Plain

0.015

36

50 × 50

0.002

Plain

0.018

81

60 × 60

0.007

Plain

0.0097

33.6

60 × 60

0.0105

Twill

0.0062

13.7

60 × 60

0.01

Twill

0.0057

11.6

70 × 70

0.004

Plain

0.0103

51.8

70 × 70

0.0045

Plain

0.0098

46.9

70 × 70

0.008

Twill

0.0063

19.4

80 × 80

0.0055

Twill

0.007

31.4

85 × 70

0.006

Plain

0

28.4

100 × 100

0.002

Plain

0.008

64

100 × 100

0.004

Plain

0.006

36

100 × 100

0.0045

Plain

0.006

30.3

200 × 200

0.0018

Plain

0.0032

41

-

Área de aplicação

1. Electrode materials for lithium batteries, nickel hydrogen batteries, fuel cells, etc

Nickel mesh is used as a current collector or carrier for supporting structures of positive and negative electrode materials.

Especially in hydrogen nickel batteries and fuel cells, the conductivity and corrosion resistance of nickel mesh are crucial.

2. Supercapacitors

Nickel mesh can serve as a supporting substrate for active materials, improving energy density and conductivity.

3. Catalyst carrier

Nickel has excellent catalytic performance, and nickel mesh is commonly used in industrial catalytic scenarios such as hydrogenation reactions.

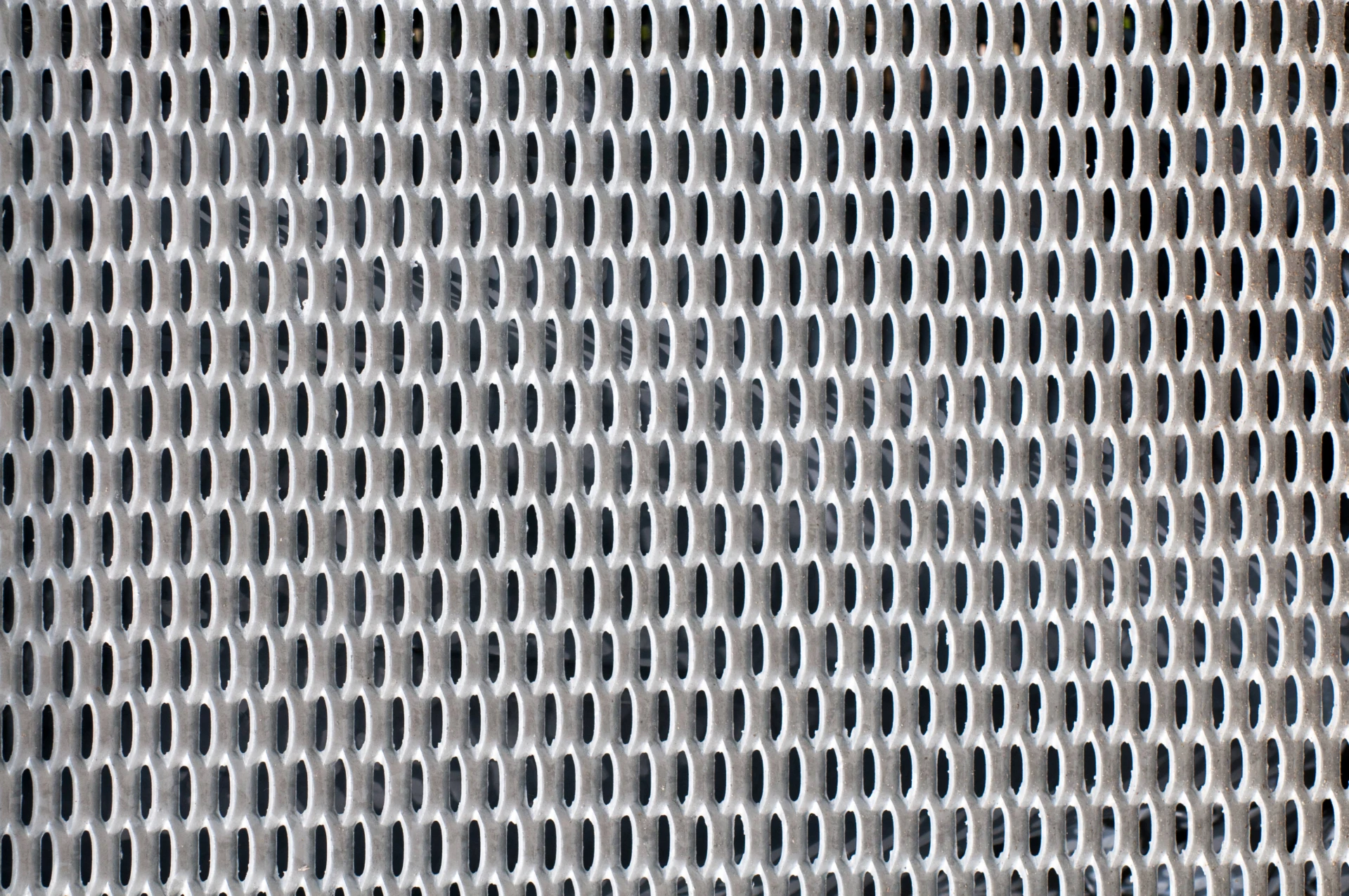

4. Filtration and Separation

Nickel mesh is used for solid-liquid separation, gas filters, etc. in high temperature and strong acid-base environments.

5. Electromagnetic shielding materials

Nickel mesh shields electromagnetic interference (EMI) and is used for military communication, electronic equipment protective cases, etc.

6. Conductive mesh material

Used in components such as thin film electrodes, heating elements, sensors, etc

-

Qual é o prazo médio de entrega?

Solicite um orçamento

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.