-

Charakterystyczne zalety

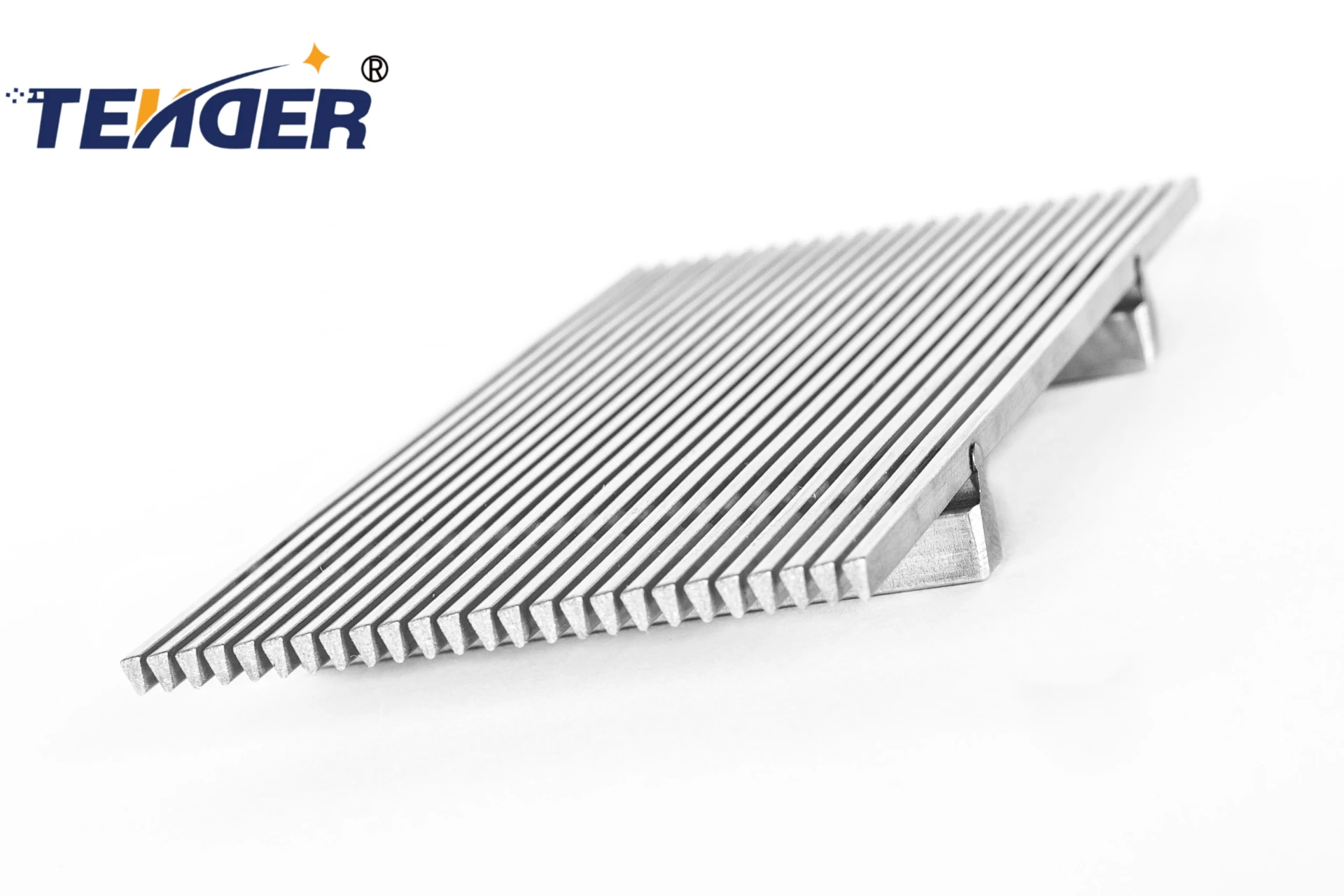

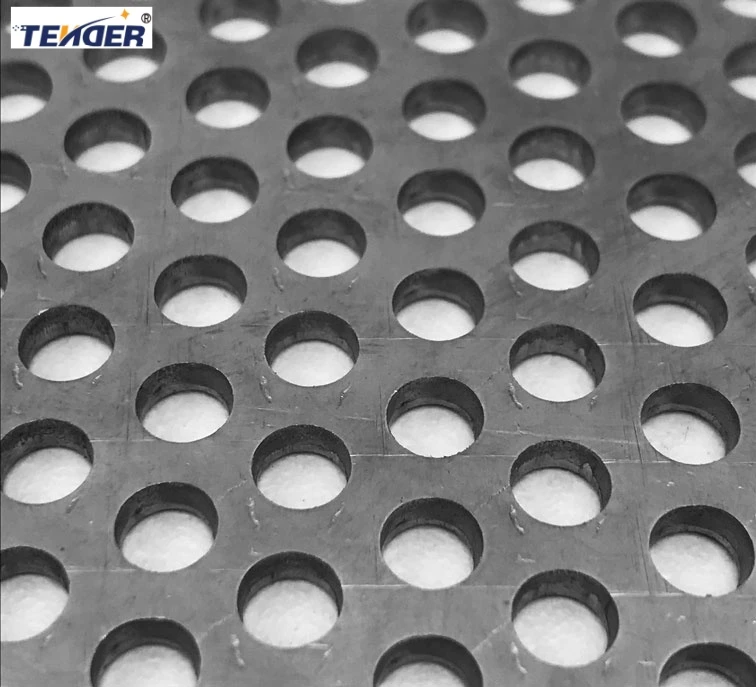

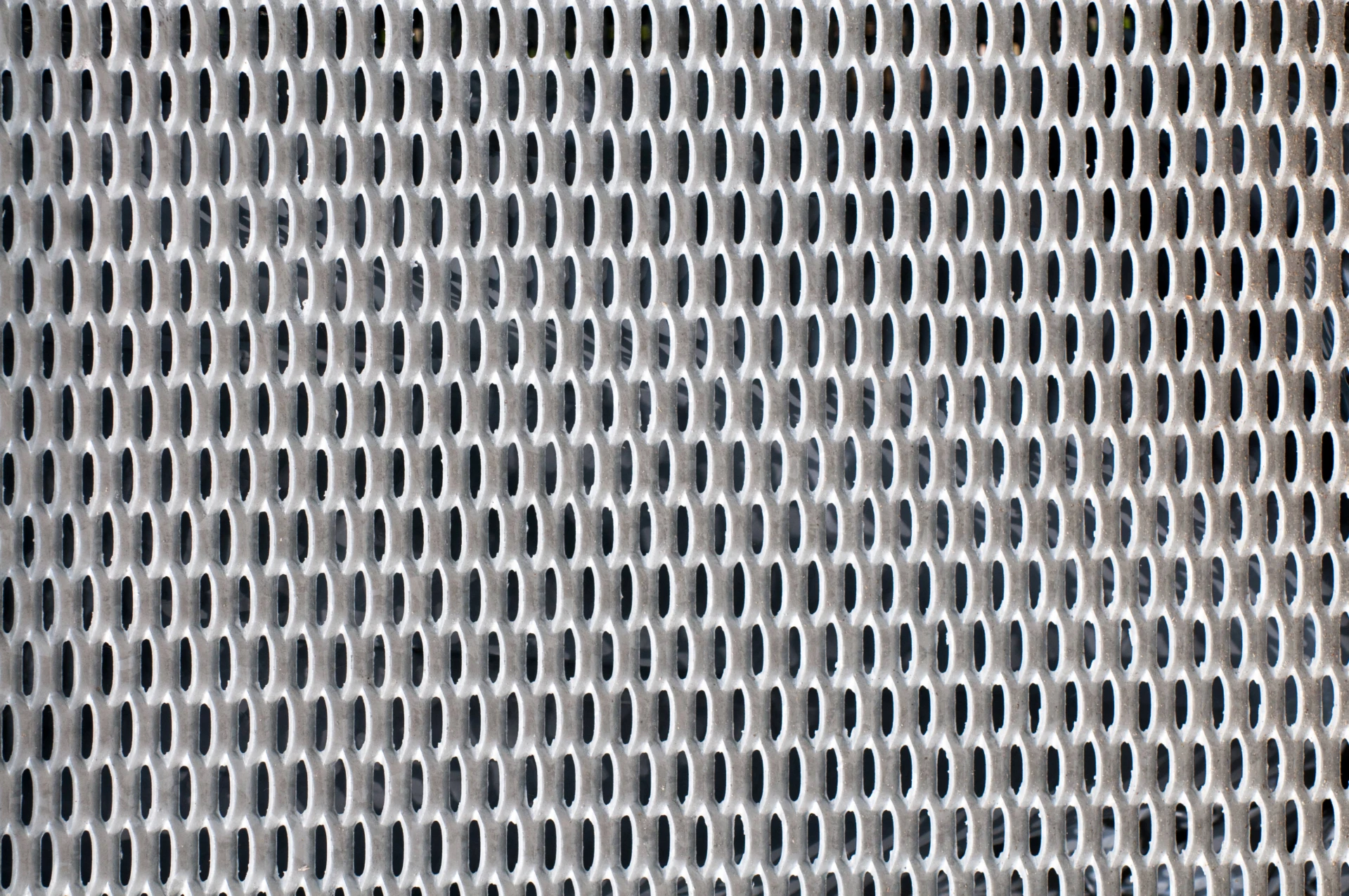

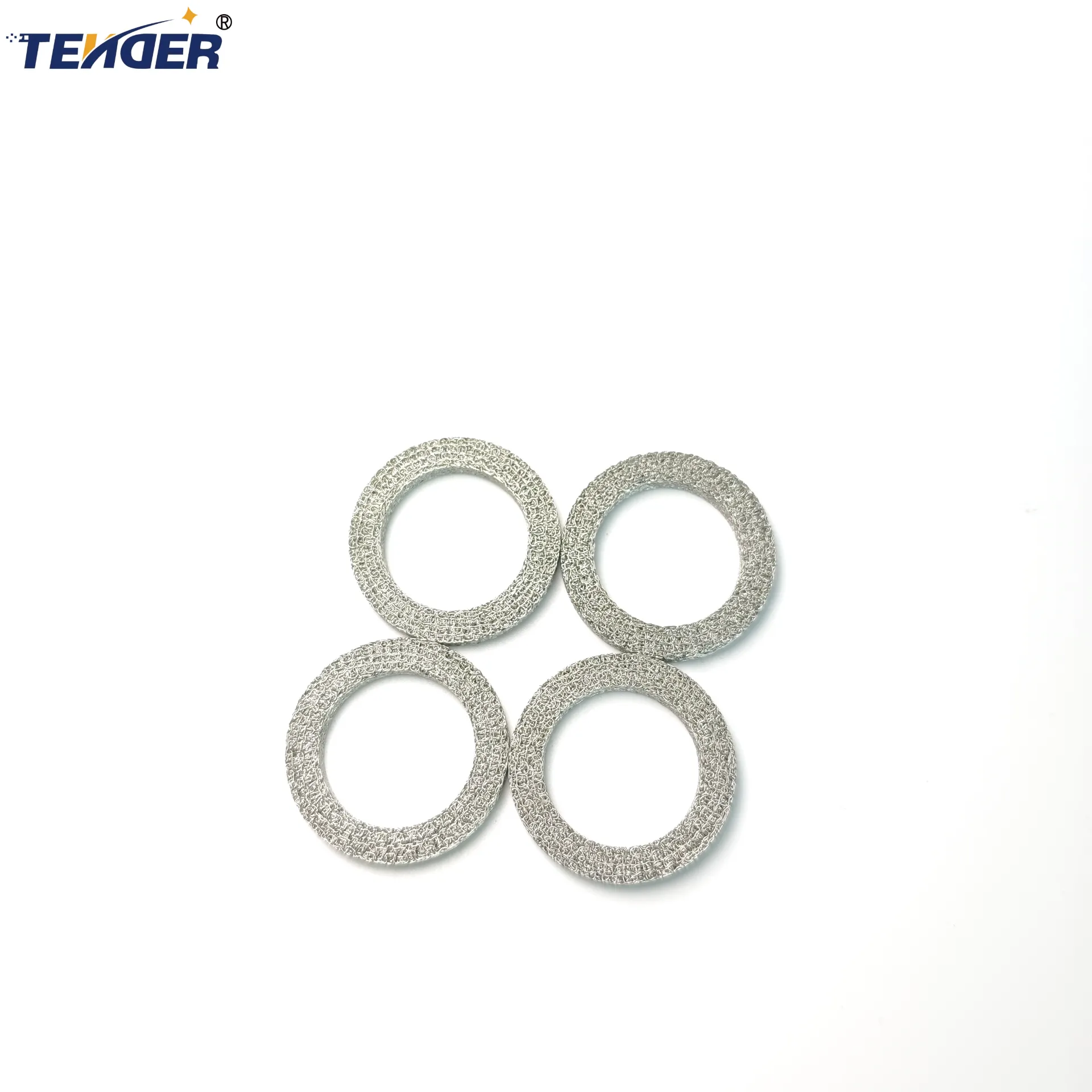

Knitted wire mesh demisters are made by knitting fine metal into a mesh structure using specialized knitting machines. The knitted mesh is then layered and compressed to the required thickness and density. Key structural features include:

Multi-layered interlocking structure: Enhances droplet capture efficiency.

Large specific surface area: Increases contact between droplets and mesh.

Lightweight and flexible: Easy to handle and install.

High porosity (typically over 98%): Low pressure drop and high gas throughput.

-

Wspólne specyfikacje

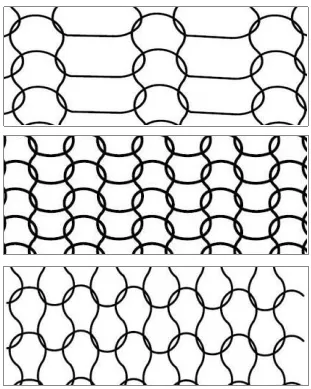

Knitted wire mesh is made by knitting machine similar to jumpers and scarves machine. The final knitted mesh is in the structure of inter-connecting loops, and it is similar to a long knit sock. We can produce multi- filament, co-knit and multi-strand knitted wire meshes. Our knit wire diameter is commonly range from 0.11 mm to 0.35 mm. But for special applications, knit wire as small as 0.03 mm or as large as 0.8 mm in diameter is available.

Tworzywo

Steel & Alloy

- Carbonsteel/SS304/SS316/SS316L/SS310S/SS304M

- Nickel/Titanium/Brass/Copper/Cr20Ni80/Cr20Ni50/Inconel

-

Density

-

-

Typ

Wire diameter (mm)

Bulk Density (kg/m3)

Specific Surface Area

(m2/m3)

Voidage

SP

Flat Wire

0.1× 0.4

168

475

0.9788

Round Wire

0.23

320

DP

Flat Wire

0.1 × 0.3

186

626

0.9765

Round Wire

0.19

484

HR

Flat Wire

0.1 × 0.4

134

313

0.9875

Round Wire

0.23

217

HP

Round Wire

0.08–0.22

128

403

0.9839

-

Application And Shape Of Knitted Demister Mesh

Typical Applications for Knitted Demister Mesh

⚫Engine crankcase breather elements.

⚫Automotive air bag filters.

⚫Air intake filters for automotive, agricultural and marine engines.

⚫Oil filler cap breathers.

⚫Fuel injector filters.

⚫Lint filters on washing machine outlet pipes.

⚫Filters for paint spray plant air outlets.

⚫Intake filters on air compressors.

⚫Bag separator layers or elements in dust collection systems.

⚫Noise attenuating filters in pneumatic tools.

⚫Coarse dust pre-filters in heating and ventilating systems.

⚫Grease filters above kitchen ranges, cookers and charcoal grills.

⚫Pre-filters and retaining/reinforcing cores in composite filters.

⚫Permanently sprayed dust filters for coal mines and quarries, etc.

⚫Silencer packings for engine exhausts.

⚫Air inlet/outlet filters for gas turbines and compressors.

-

Jaki jest średni czas realizacji zamówienia?

Poproś o wycenę

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.