The German client, a specialist in automated equipment, sought a solution that would address the limitations of traditional belts—such as frequent joints, uneven tension, and inconsistent hole patterns. These issues often hinder production efficiency and product quality.

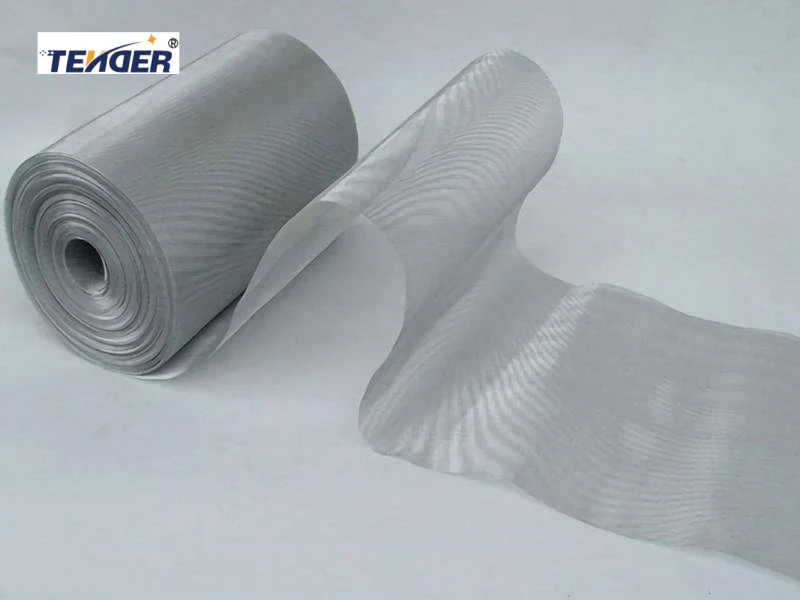

Upon in-depth consultation, the TENDER technical team swiftly initiated a dedicated R&D program. By customizing the tooling system, optimizing the perforation layout, and refining tension control processes, the team successfully developed a seamless, ultra-long perforated metal belt with consistent accuracy and exceptional durability

Key features of the product include:

High precision perforation: 0.5×3 mm slot holes with a tolerance of ±0.05 mm

Seamless, one-piece construction: Ensures smooth operation with no joints

Excellent wear and corrosion resistance: Ideal for applications in food processing, electronics, pharmaceuticals, and automated production

Total length of 25 meters: Reduces the need for frequent replacements and improves line efficiency

After on-site testing, the German client praised the product’s outstanding performance and precision, stating that it "fully meets German industrial standards and significantly enhances the efficiency of our automation systems."

With decades of experience in metal mesh manufacturing, TENDER Wire Mesh Group integrates material selection, mold development, and equipment production into a unified system. Its products are exported to over 50 countries and regions including Europe, North America, and Southeast Asia.

This successful cooperation not only reflects the client’s recognition of TENDER’s technical capabilities but also paves the way for deeper expansion into the European market.

TENDER remains committed to its core mission: “Excellence in Mesh, Expertise in Customization.” The company will continue pushing boundaries in precision manufacturing, offering global clients reliable, efficient, and tailor-made wire mesh solutions.