-

Characteristic Advantages

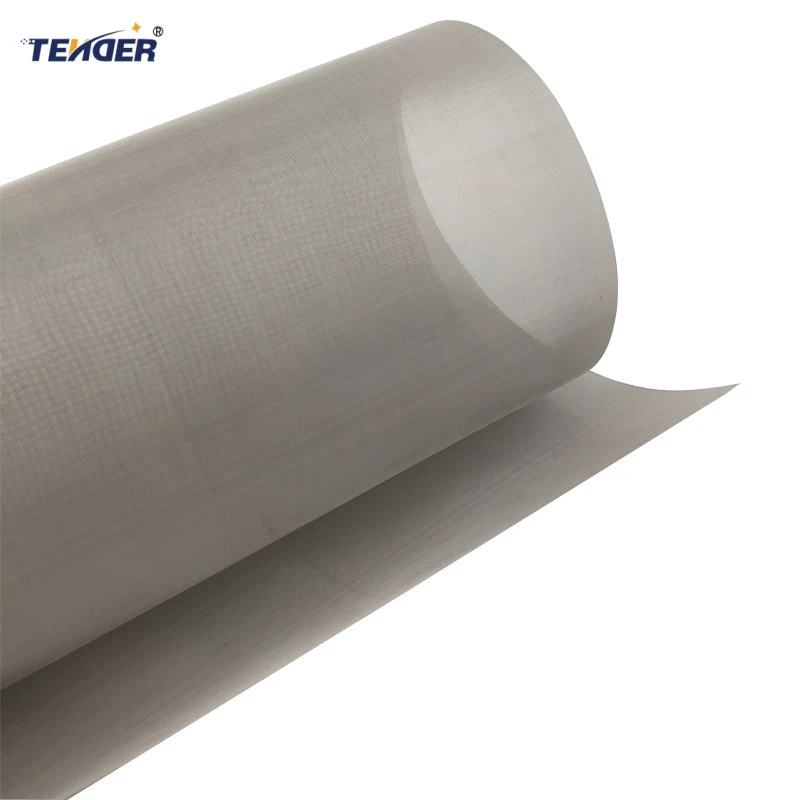

- Strong corrosion resistance, stable to seawater, acidic and alkaline solutions, chlorides, nitric acid, aqua regia, etc

- Lightweight, high strength, and density are about 60% of stainless steel, with a higher specific strength than most metals

Although not as good as copper in terms of thermal and electrical conductivity, it meets most engineering requirements

- Non magnetic is suitable for applications such as medical and electronic industries that require non-magnetic properties

- Good biocompatibility for medical implantation and fluid contact environments

6 can be used at high temperatures with a melting point of about 1660 ° C and a working temperature of up to 600 ° C+

-

Common Specifications

Grade

Material Type

Key Characteristics

Typical Applications

Grade 1

Commercially Pure Titanium (CP Ti)

Softest and most ductile; excellent corrosion resistance; high formability

Chemical processing, marine components, medical instruments

Grade 2

Commercially Pure Titanium (CP Ti)

Most widely used grade; good strength-to-weight ratio; excellent corrosion resistance

Heat exchangers, pressure vessels, desalination, architectural mesh

Grade 3

Commercially Pure Titanium (CP Ti)

Higher strength than Grades 1 & 2; slightly lower ductility

Aerospace structures, chemical tanks, piping systems

Grade 4

Commercially Pure Titanium (CP Ti)

Highest strength among CP grades; excellent corrosion resistance

Aircraft components, surgical hardware, marine environments

Grade 5

Titanium Alloy (Ti-6Al-4V)

Most commonly used alloy; very high strength; good weldability; high temperature service

Aerospace, medical implants, racing, industrial fasteners

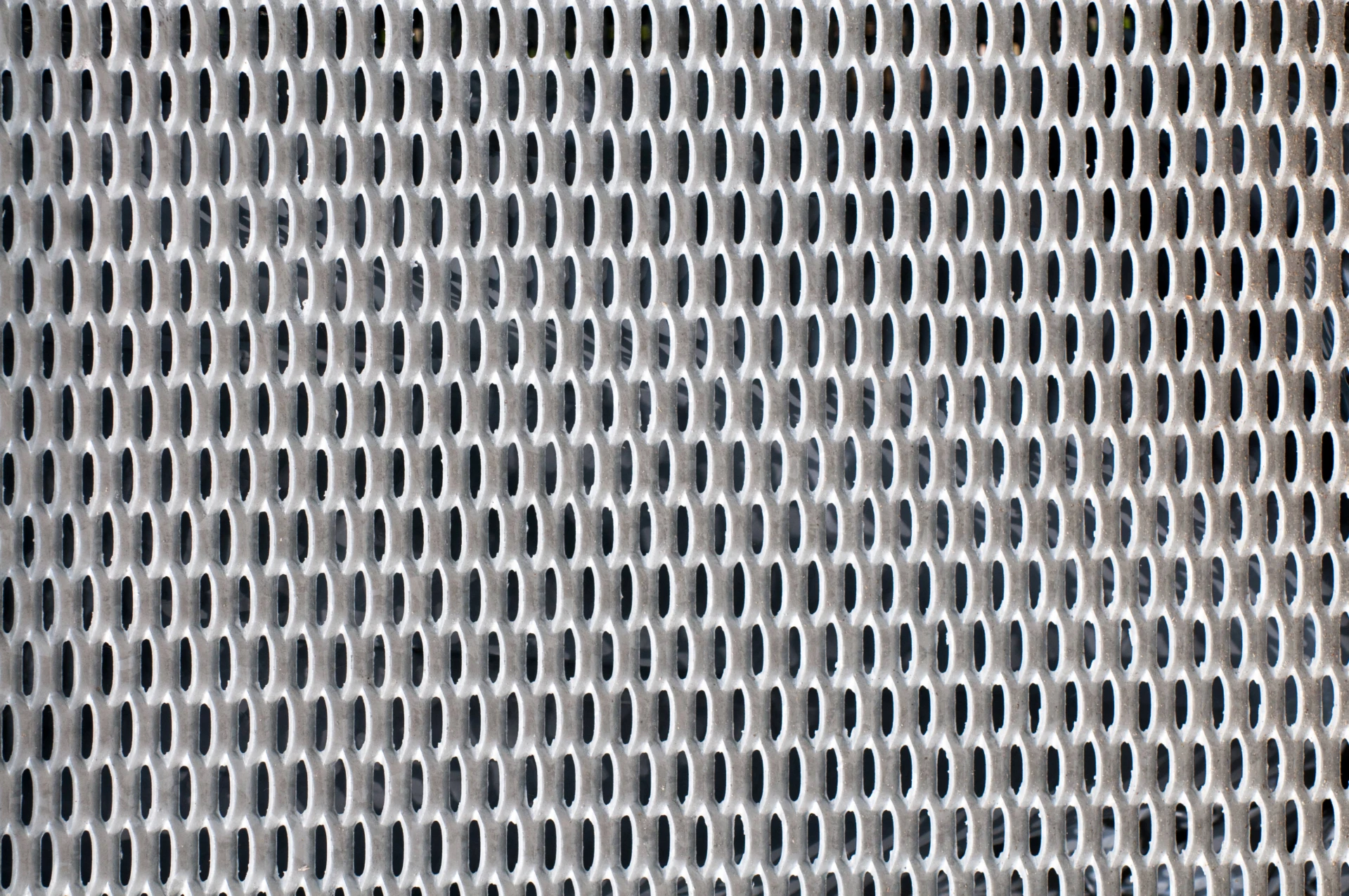

Mesh Count(目数)

Wire Diameter (mm / inch)

Aperture Size (mm / inch)

Open Area (%)

Weave Type

Typical Applications

4 × 4

1.00 mm / 0.0394"

5.35 mm / 0.2106"

~74%

Plain Weave

Marine cage mesh, heavy-duty filter

10 × 10

0.60 mm / 0.0236"

1.94 mm / 0.0764"

~60%

Plain Weave

Anode mesh, seawater filtration

16 × 16

0.40 mm / 0.0157"

1.19 mm / 0.0468"

~57%

Plain Weave

Chlor-alkali electrolysis

20 × 20

0.35 mm / 0.0138"

0.92 mm / 0.0362"

~51%

Plain / Twill

Electrochemical filter, battery separator

40 × 40

0.20 mm / 0.0079"

0.43 mm / 0.0169"

~44%

Twill Weave

Fine filtration, catalyst carrier

60 × 60

0.15 mm / 0.0059"

0.27 mm / 0.0106"

~40%

Twill Weave

Electroplating support mesh

80 × 80

0.12 mm / 0.0047"

0.20 mm / 0.0079"

~36%

Dutch Weave

Gas diffusion layer, precision filtration

100 × 100

0.10 mm / 0.0039"

0.15 mm / 0.0059"

~30%

Dutch Weave

Fuel cell component, microfiltration

150 × 150

0.07 mm / 0.0028"

0.10 mm / 0.0039"

~28%

Dutch Weave

High purity chemical filtration

200 × 200

0.05 mm / 0.0020"

0.077 mm / 0.0030"

~25%

Reverse Dutch

Semiconductor liquid filter, ultrafiltration

-

Application Area

Application Field

Description / Usage

Marine Engineering / Shipbuilding

Resistant to seawater corrosion; used in ship window screens, anti-fouling nets, marine filters

Chemical Processing / Acid-Alkali Systems

Ideal for corrosive environments; used as acid-washing mesh, filtration mesh, or electrochemical mesh

Electroplating & Electrolysis

Commonly used as anode/cathode mesh or conductive support mesh in electrolytic processes

Aerospace Industry

Lightweight and strong; used in fuel system filters, reinforcement mesh, or shielding layers

Medical & Biomedical Applications

Excellent biocompatibility; used for surgical mesh, bone scaffolds, and implant filters

Nuclear & Power Generation

High temperature and corrosion resistance; used in heat exchangers, nuclear reactor shielding

Environmental Filtration Equipment

Applied in gas filtration, wastewater treatment, and as catalyst support mesh

Desalination / Water Treatment

Used in pre-filtration for reverse osmosis, electrolysis electrodes, and corrosion-resistant barriers

Fuel Cells & Hydrogen Industry

Serves as gas diffusion layers (GDL), current collectors, and electrode supports

Laboratory & Scientific Equipment

High corrosion resistance; ideal for sieving, filtration, and controlled environment tests

Precision Electronics / Semiconductors

Used in cleanroom filters, sputtering target protection, and static-resistant shielding

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.