-

Characteristic Advantages

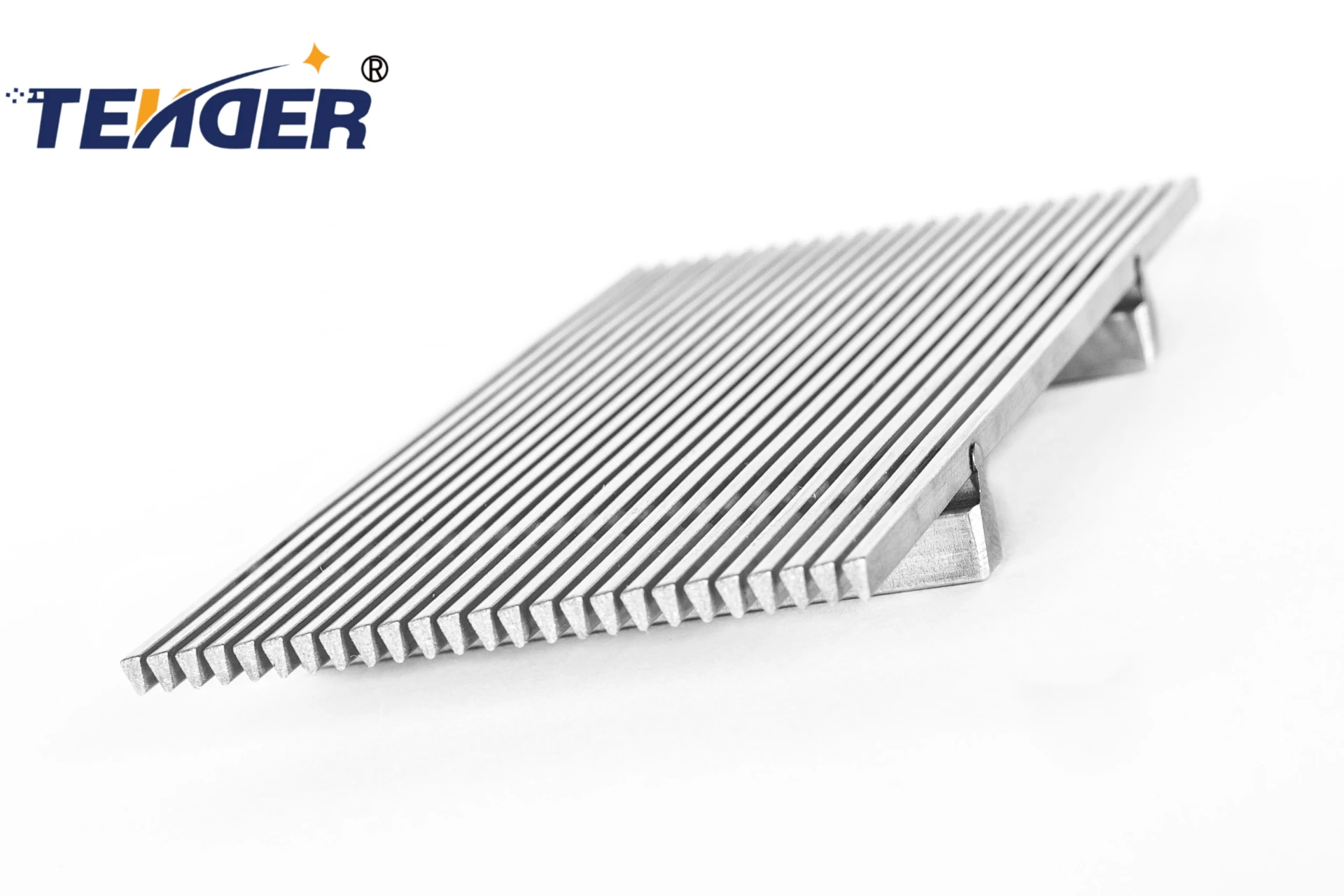

- High strength and strong compression resistance: suitable for high-pressure and high flow rate environments;

- Diverse pore sizes and good permeability: can accurately control pore size and opening rate;

- Stable structure and not easily deformed: suitable for repeated cleaning and long-term use;

- Can be used in combination with woven mesh and sintered mesh to improve filtration efficiency;

- Support multiple welding and connection methods: adapt to different working conditions and interface requirements

-

Common Specifications

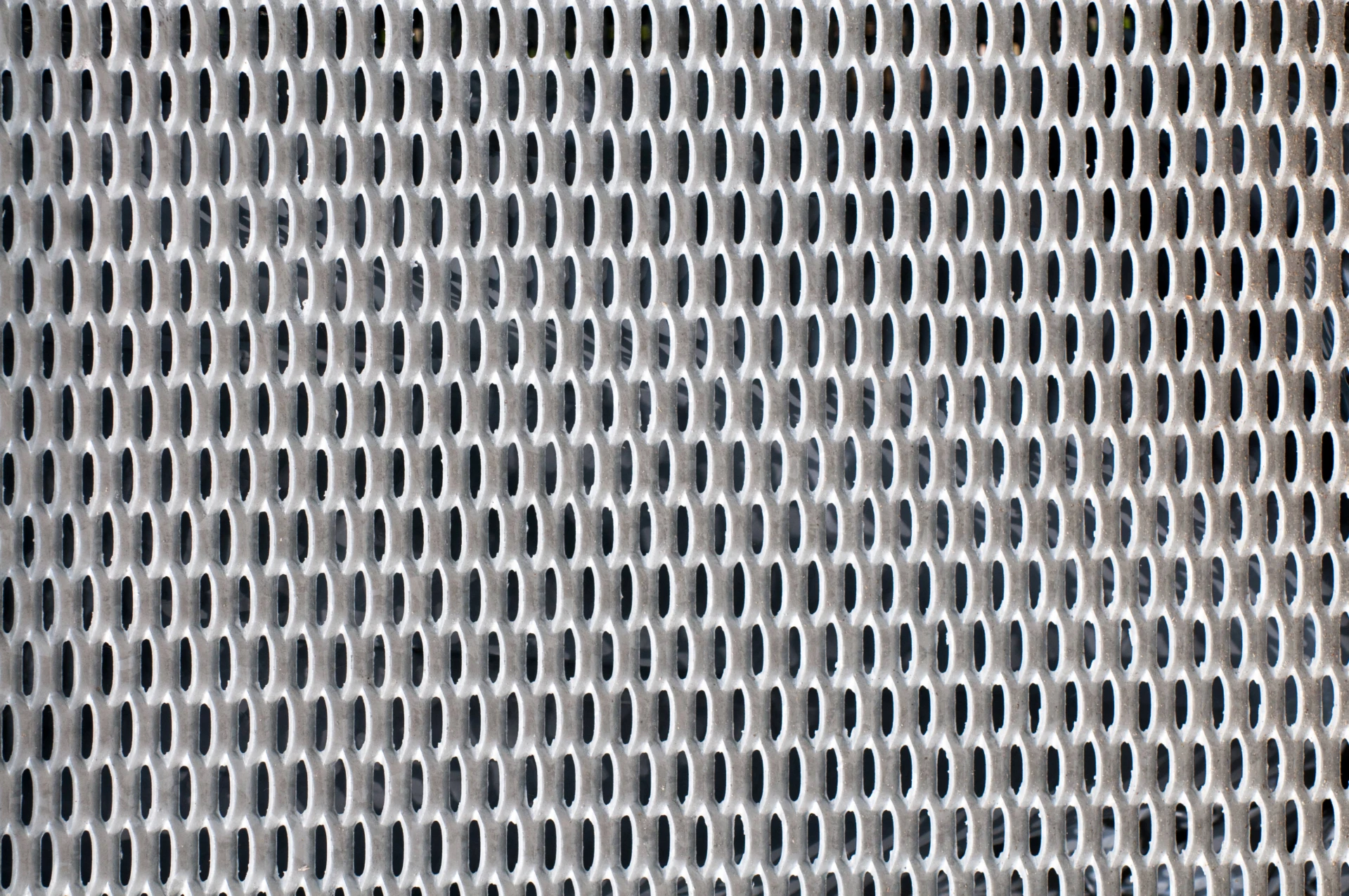

Perforation Types

Circular hole (most common)

Elliptical hole

Longhole (elongated hole, slotted hole)

square hole

Customized shapes such as hexagonal holes and bridge holes

Parameter

Typical Values / Options

Material

SS304, SS316, SS316L, Carbon Steel, Aluminum, Titanium

Tube Diameter (OD)

20 mm – 300 mm

Length

50 mm – 1200 mm

Thickness of Plate

0.3 mm – 2.0 mm (standard: 0.5–1.5 mm)

Hole Diameter

0.5 mm – 10 mm

Hole Pattern

Round, slot, square, staggered or straight pitch

Open Area (Porosity)

10% – 60%

Support Structure

Optional inner or outer mesh (woven/sintered)

End Types

Flat, threaded, flanged, closed-end, custom

Connection Methods

Argon arc welding, spot welding, laser welding, bonding

Working Temperature

Up to 600°C (material dependent)

Working Pressure

Up to 5 MPa or more (depending on thickness and structure)

Cleaning Methods

Ultrasonic, backflush, solvent cleaning

-

Application Area

- Petrochemical filtration (crude oil, water, gas filtration)

- Pre filtration of water treatment system

- Particle interception in the food and beverage industry

- Filter housing for agricultural irrigation system

- Protection and filtration of hydraulic oil and lubricating oil systems

- Pre filtration of medical equipment and sterilization devices

- Dust removal and interception of powder conveying system

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.