-

Characteristic Advantages

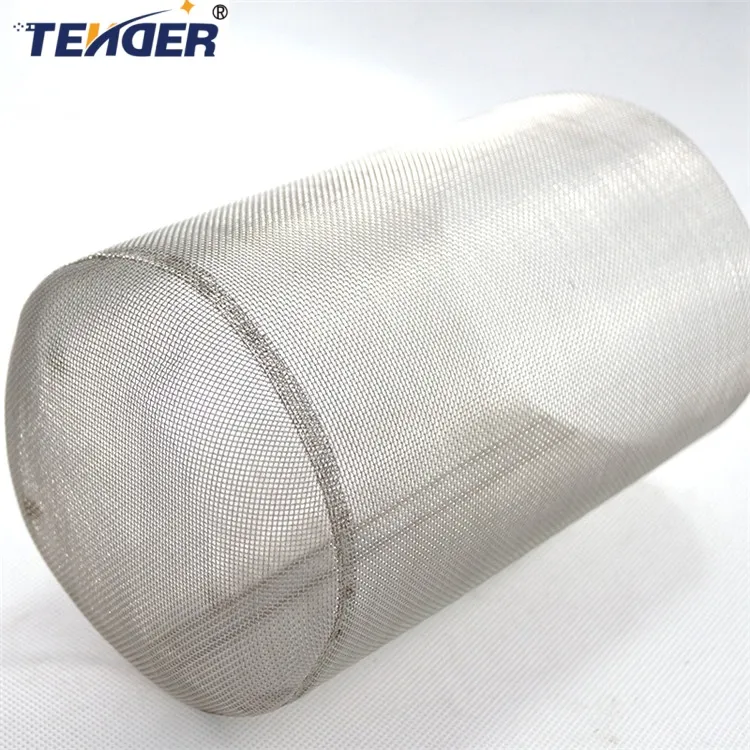

- High permeability: The metal woven structure ensures good fluid permeability;

- Flexible filtering accuracy options: from tens of micrometers to hundreds of micrometers;

- Reusable cleaning and use: Long service life, suitable for multiple cleaning and reuse;

- Diverse structures: can be single-layer, double-layer, or multi-layer mesh tube structures;

- Diverse interface forms: customizable interfaces, lengths, diameters, etc. according to customer requirements;

- Temperature and corrosion resistance: Especially suitable for harsh environments such as high temperature, acid and alkali.

-

Common Specifications

Parameter

Typical Range / Options

Material

Stainless Steel 304, 316, 316L; also Monel, Inconel, Hastelloy, Brass

Filter Media Type

Woven wire mesh: plain weave, twill weave, Dutch weave

Outer Diameter (OD)

10 mm – 200 mm (customizable)

Length

20 mm – 1000 mm (standard sizes: 100 mm, 200 mm, 500 mm, etc.)

Mesh Size

10 – 500 mesh (equivalent to ~2000 μm – 20 μm)

Filtration Accuracy

20 μm – 500 μm (depends on mesh and layering)

Number of Layers

Single-layer, double-layer, or multi-layer (up to 5 layers)

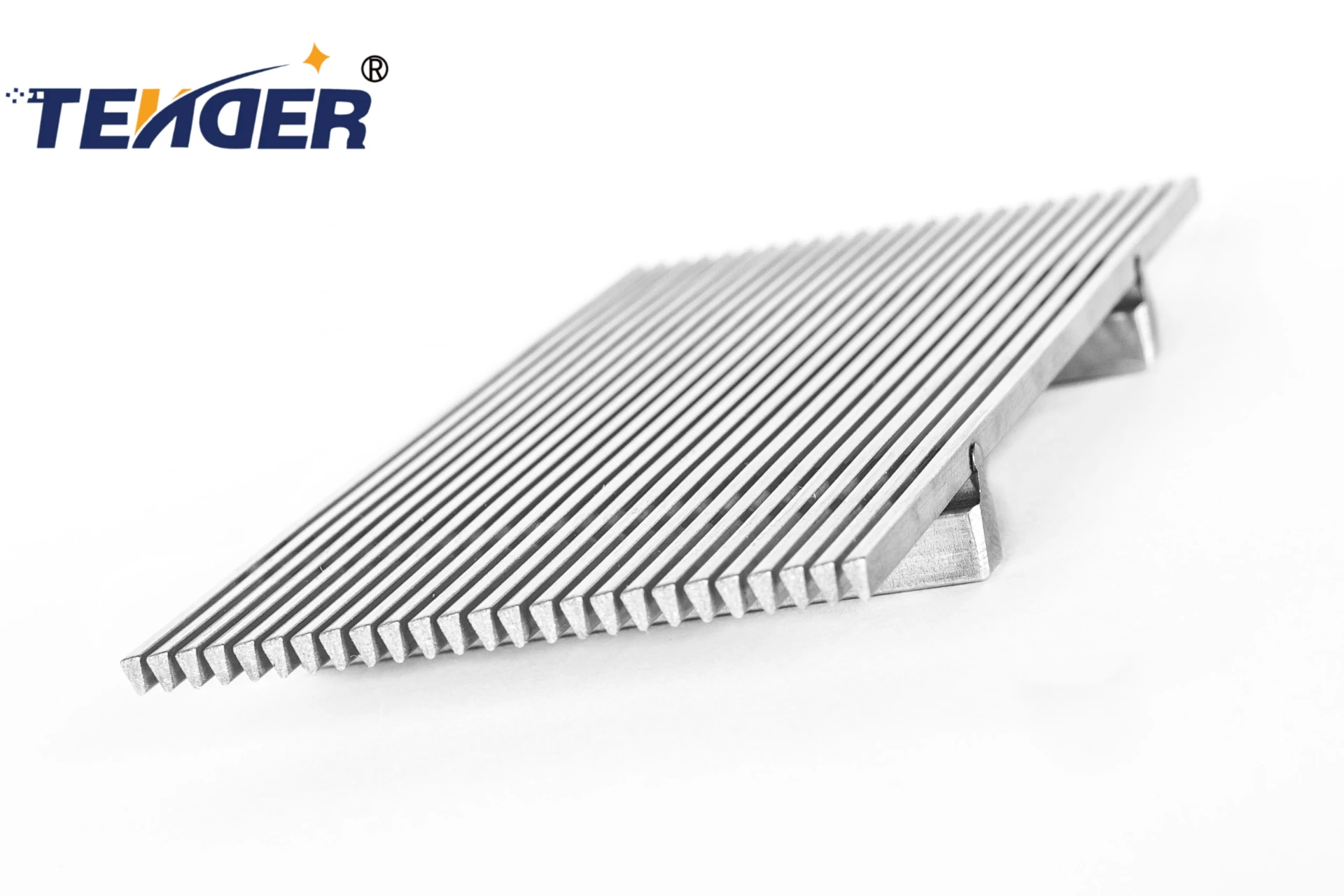

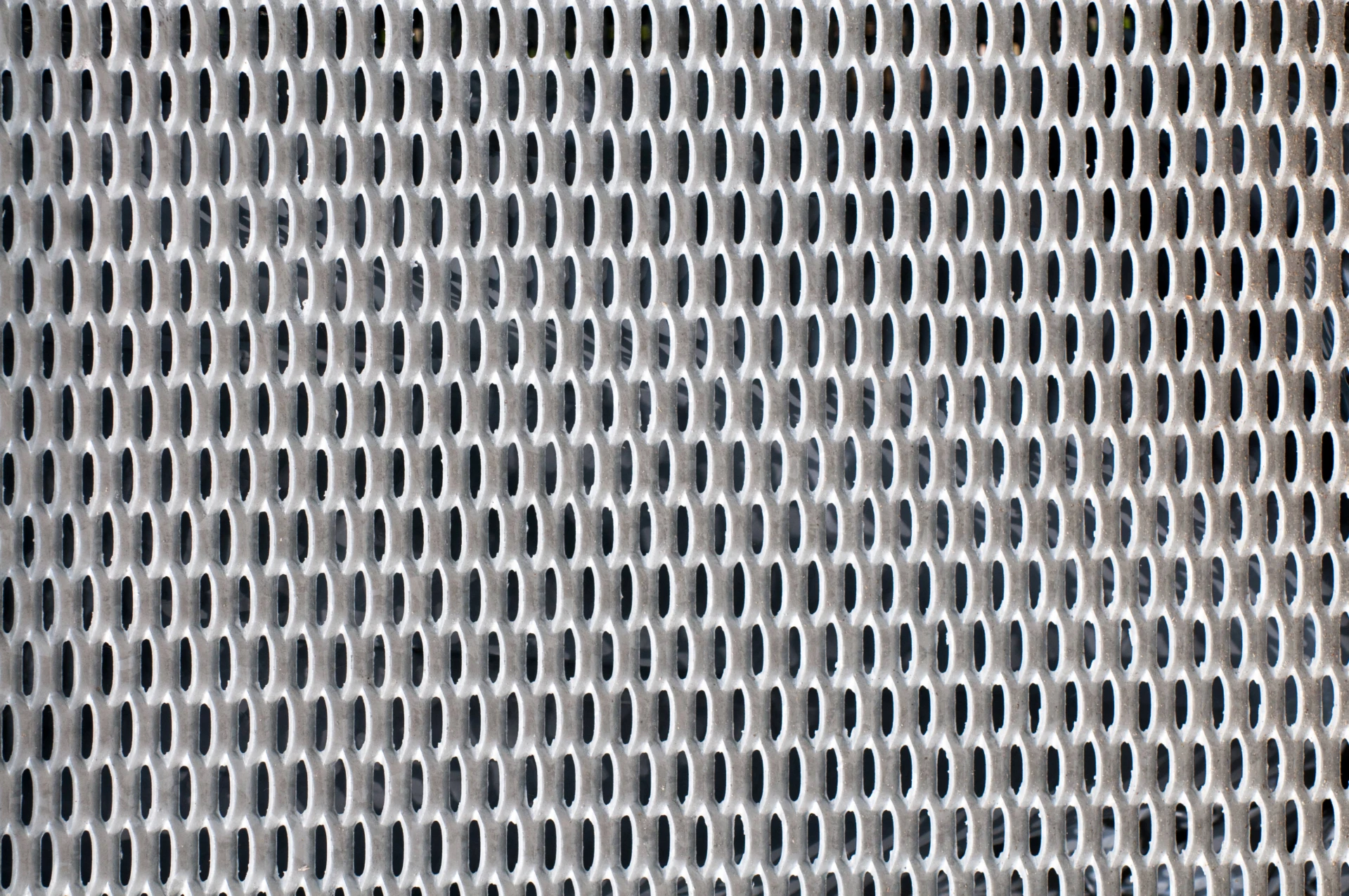

Support Structure

Inner perforated tube (optional), outer protection layer (optional)

End Style

Open both ends, closed one end, threaded ends, flange ends, custom

Connection Types

NPT/BSP thread, clamp, flange, bayonet, push-fit

Working Temperature

-200°C to +600°C (depends on material)

Working Pressure

Up to 2 MPa typically (higher with reinforced structure)

Cleaning Methods

Backflushing, ultrasonic cleaning, chemical soaking

-

Application Area

- Hydraulic system oil filtration

- Pre filtration of pipeline impurities (protecting pumps, valves, and instruments)

- Particle interception in water treatment systems

- Filtration of chemical fluids and viscous liquids

- Filtering of impurities in food and beverage raw materials

- Filtration of cooling water system in power plants

- Aerospace and mechanical lubrication filtration protection

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.