-

Characteristic Advantages

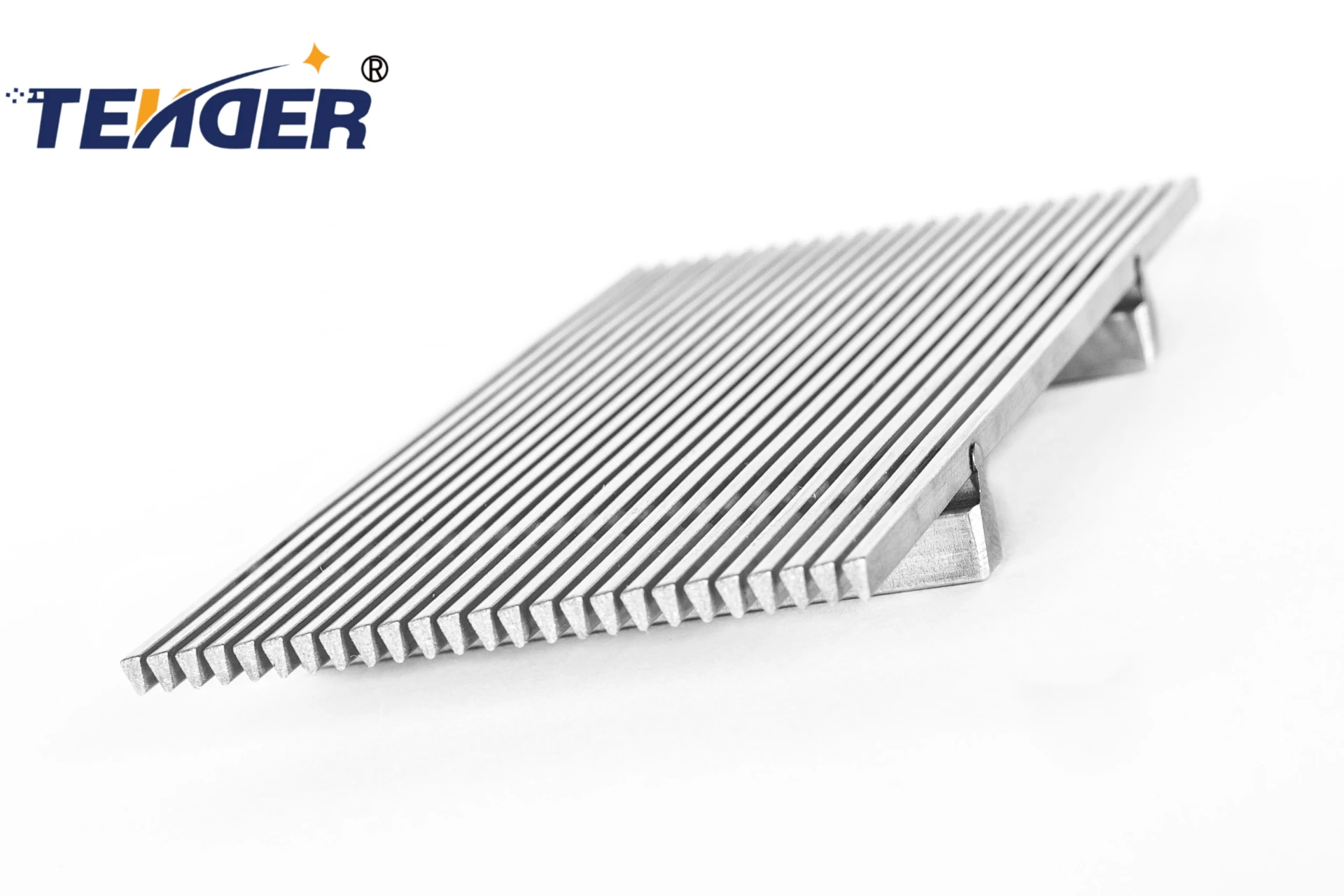

- Large filtration area: The folding structure increases the filtration area per unit volume.

- Reusable cleaning and use: It can be cleaned multiple times using methods such as ultrasonic waves or reverse flushing.

- High temperature and corrosion resistance: Made of materials such as stainless steel, Monel, titanium, etc., suitable for harsh environments.

- Sturdy structure, not easily deformed: suitable for high-pressure and high-speed fluid filtration applications.

- The filtering accuracy can be customized: from tens of micrometers to hundreds of micrometers.

-

Common Specifications

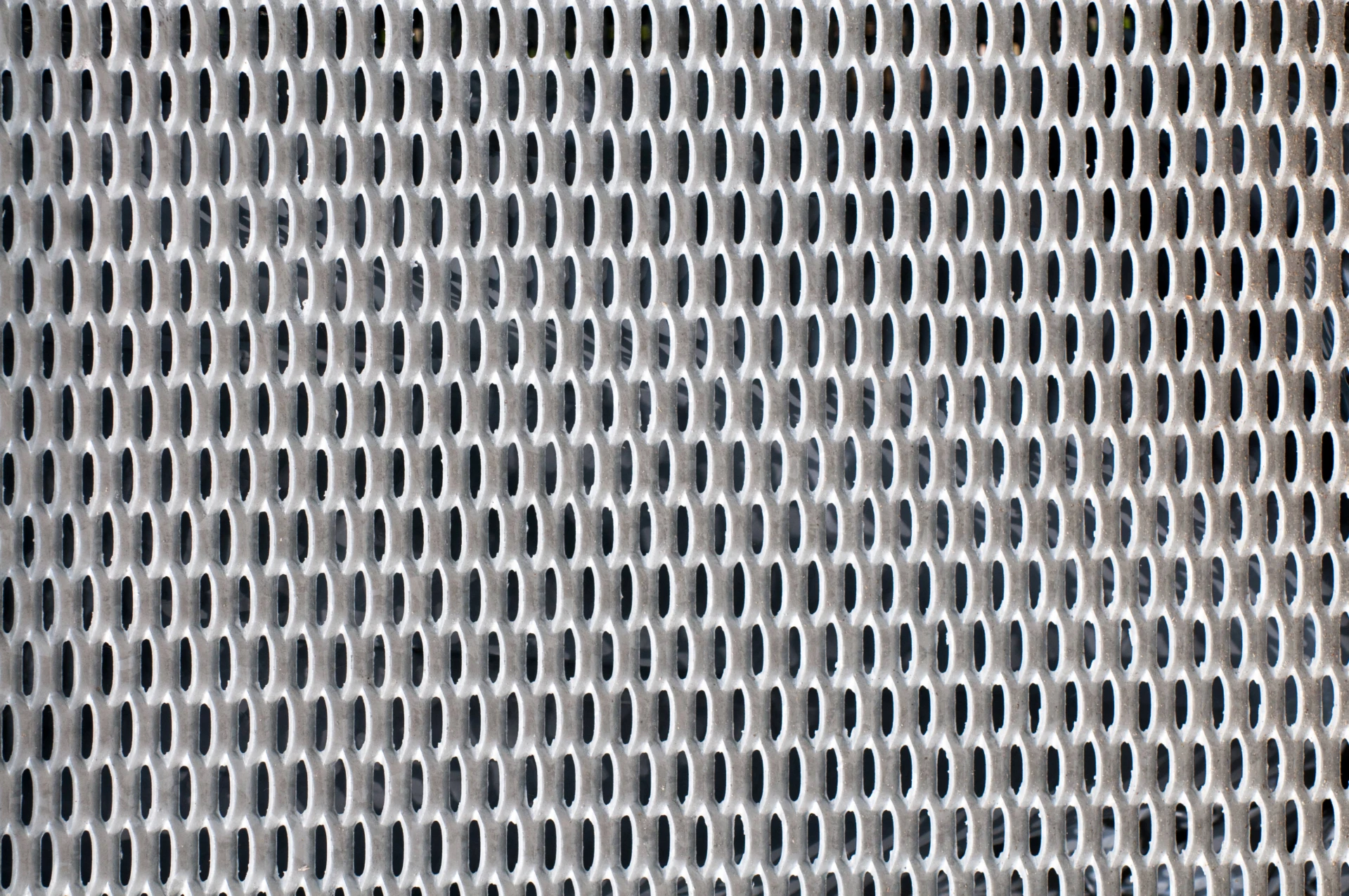

- Filter layer material: stainless steel woven mesh, stainless steel sintered mesh, multi-layer composite mesh

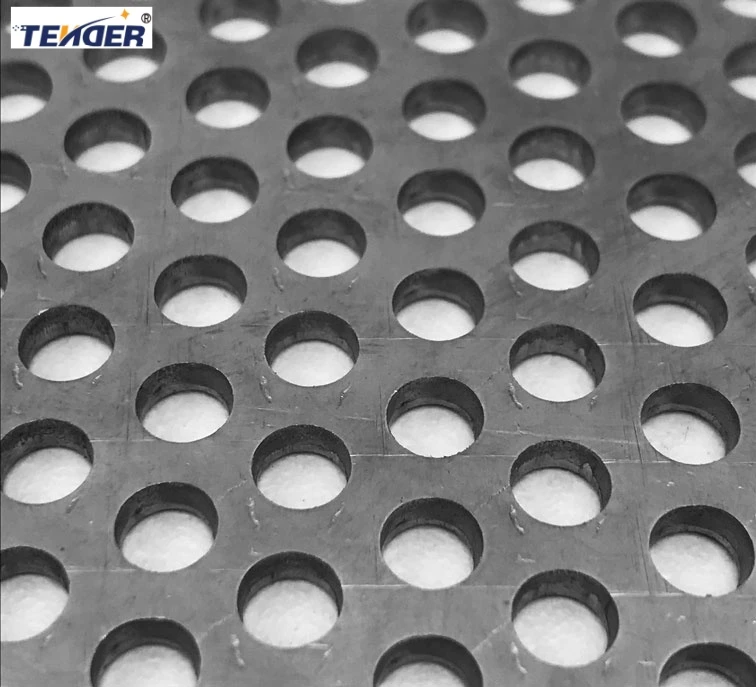

- Inner skeleton: perforated stainless steel support tube

- End cap: stainless steel or carbon steel, welded or bonded for fixation

- Sealing methods: silicone ring, fluororubber ring, metal welding, etc

-

Parameter

Common Range / Options

Outer Diameter (OD)

25 mm – 150 mm (1" – 6")

Length

50 mm – 1000 mm (2" – 40") or customized

Filtration Accuracy

1 μm – 500 μm (standard: 5, 10, 25, 50, 100, 200, 300 μm)

Filter Media

Stainless steel woven mesh, sintered mesh, multi-layer composite mesh

Mesh Type

Plain weave, twill weave, Dutch weave, sintered five-layer mesh

Number of Pleats

20 – 80 pleats (depends on length and diameter)

Pleat Height

8 mm – 30 mm

Effective Filtration Area

2 – 10 times greater than non-pleated filters of same size

End Cap Material

Stainless steel 304/316, galvanized steel, aluminum

Core/Support Tube

Perforated stainless steel tube (304 or 316), optional inner and outer layers

Sealing Method

Argon arc welding, epoxy bonding, silicone/Viton/PTFE O-ring

Working Temperature

-200°C to +600°C (depending on material)

Working Pressure

Up to 30 MPa (300 bar), depending on wall thickness and structure

Flow Direction

Inside to outside (standard), or outside to inside

Cleaning Method

Ultrasonic cleaning, backflushing, chemical cleaning

Connection Type

Threaded (NPT/BSP), flange, clamp, quick-connect, customized

-

Application Area

1.Petrochemical equipment filtration

2.Hydraulic and lubrication system

3.Pharmaceutical and food processing equipment

4.Water treatment system

5.Aerospace and nuclear power plant filtration equipment

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.