-

Characteristic Advantages

- High precision: capable of achieving a machining accuracy of ± 0.01mm

- Flexible hole type: can be designed with any shape, density, and arrangement

- Smooth edges: no burrs, no deformation

- No mechanical stress: does not damage the material structure

- Mass production: suitable for mass production of products with high consistency

-

Common Specifications

Parameter Category

Description

Common Range

Example

Hole Diameter

Diameter of the perforations

0.5mm – 100mm (Common: 1mm, 2mm, 5mm, 10mm)

Example: 2mm round hole means each hole has a 2mm diameter

Sheet Thickness

Thickness of the metal sheet

0.3mm – 10mm (Common: 0.5mm, 1mm, 1.5mm, 2mm, 3mm)

Thicker plates offer more strength but are heavier and harder to process

Pitch (Center Distance)

Distance between centers of adjacent holes

Typically 1.5 – 3× the hole diameter

Example: 2mm hole, 3mm pitch

Open Area (Porosity)

Percentage of the total sheet area that is open/perforated

20% – 80%

Higher open area = better airflow or light transmission

Hole Arrangement

Hole layout pattern

Straight (90°), Staggered (60°), Horizontal or Vertical arrangement

Staggered layout offers better strength and aesthetics

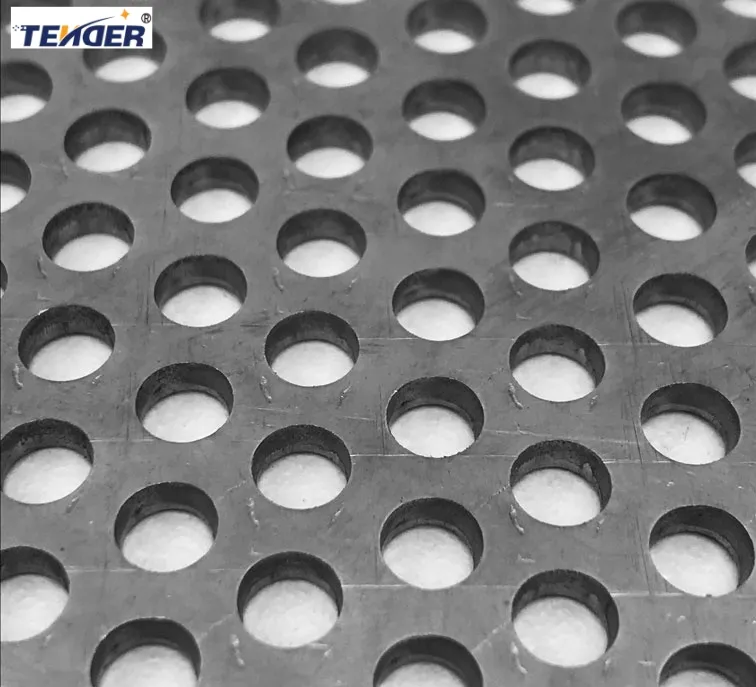

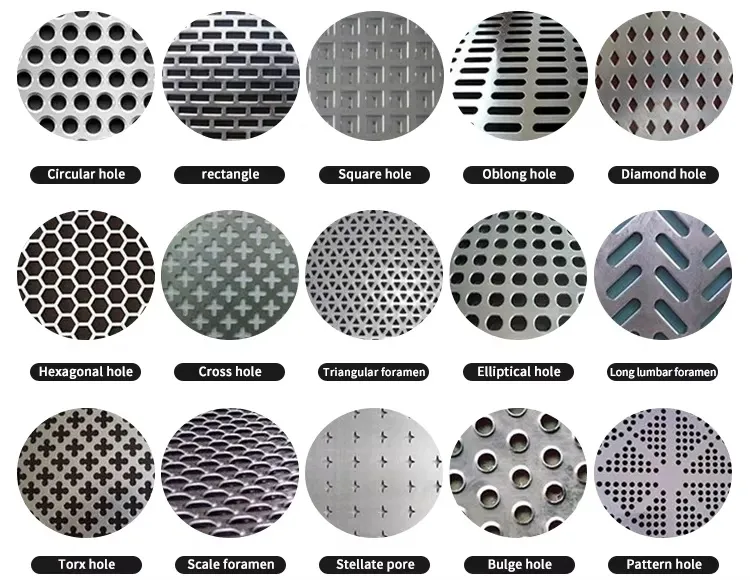

Common Hole Shapes

Perforation geometry

Round, Slotted (Oblong), Square, Hexagonal, Diamond, Custom designs

Round holes are the most common

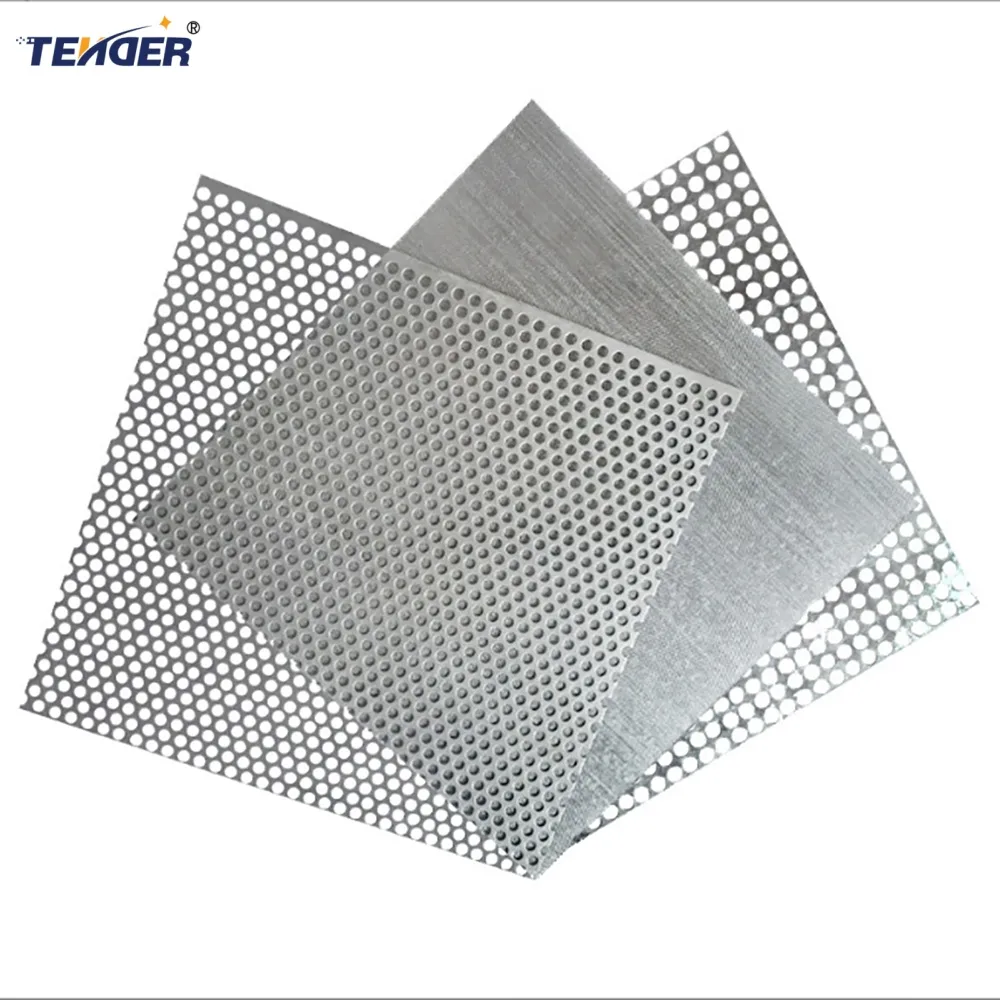

Standard Sheet Size

Dimensions of a full sheet

Common sizes: 1000×2000mm1220×2440mm

1250×2500mm1500×3000mm

Custom sizes or coil supply available on request

Edge Treatment

Whether edges are deburred or rolled

Clean edge, burr edge, rolled edge

Rolled edges used for safety or design requirements

Material Type

Base metal materials

Stainless steel, carbon steel,

aluminum, copper, titanium,

galvanized steel, plastic, etc.

Different materials offer varying levels of corrosion resistance and strength

Hole Diameter

Pitch (Center Distance)

Thickness

Open Area (Approx.)

Hole Shape

Pattern

1

2

0.5

23%

Round

60° staggered

2

3

1

40%

Round

Straight

3

5

1.2

33%

Round

60° staggered

5

8

1.5

37%

Round

Straight

10

15

2

40%

Round

Staggered

0.5×5.0

8

1

32%

Slotted

Straight

10×10

14

1.5

50%

Square

Straight

-

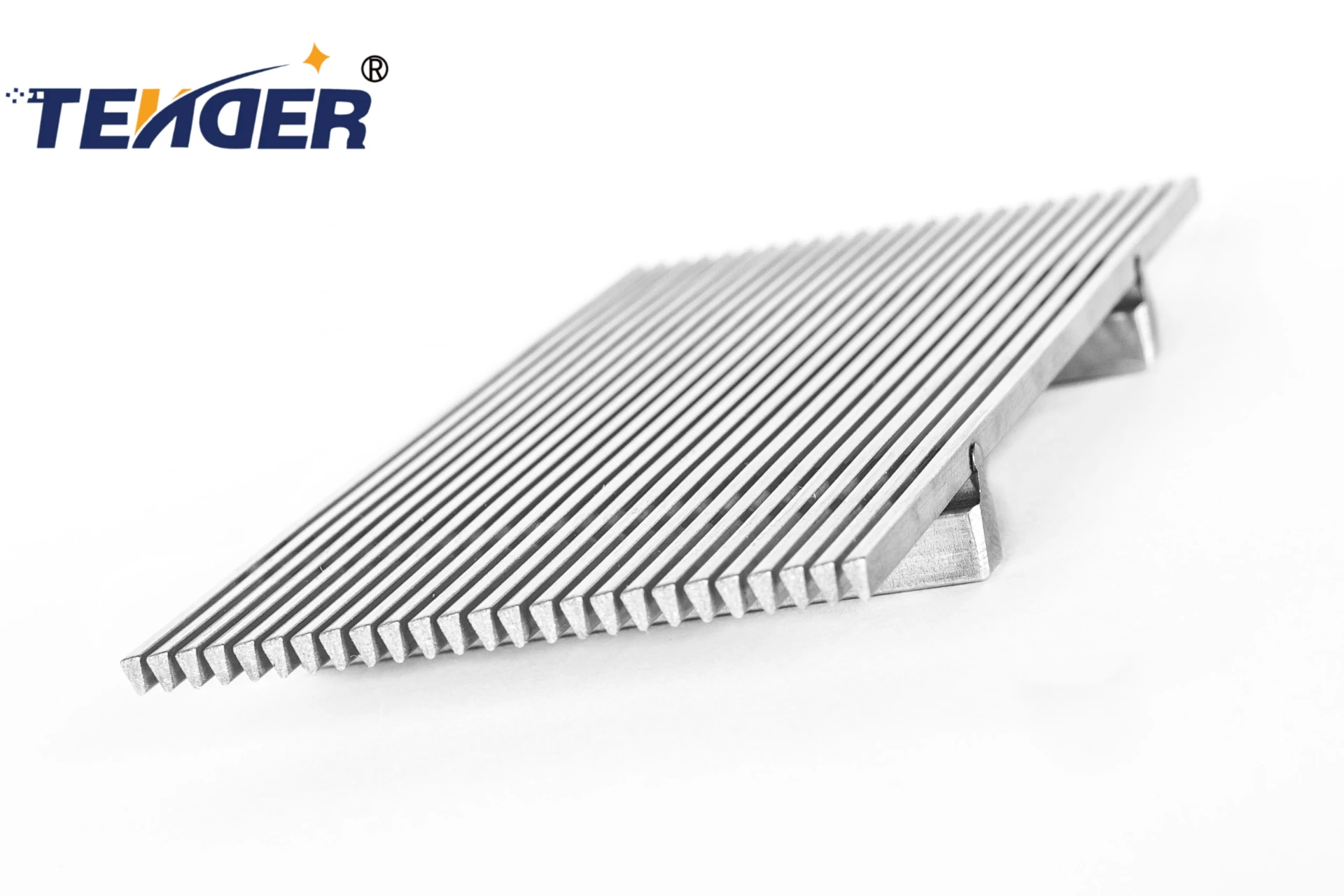

Application Area

Application

Suggested Specification

Ventilation / Heat Dissipation

Thin sheets, high open area (e.g., 1mm holes, 60% open area)

Screening / Filtering

Small holes, dense patterns (e.g., 1.5mm staggered holes)

Machine Guarding

Thicker sheets with larger holes (e.g., 10mm holes, 2mm thick)

Architectural Decoration

Custom hole designs, balance between aesthetics and strength

Acoustic Panels

High open area with small round or hexagonal holes

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.