-

Characteristic Advantages

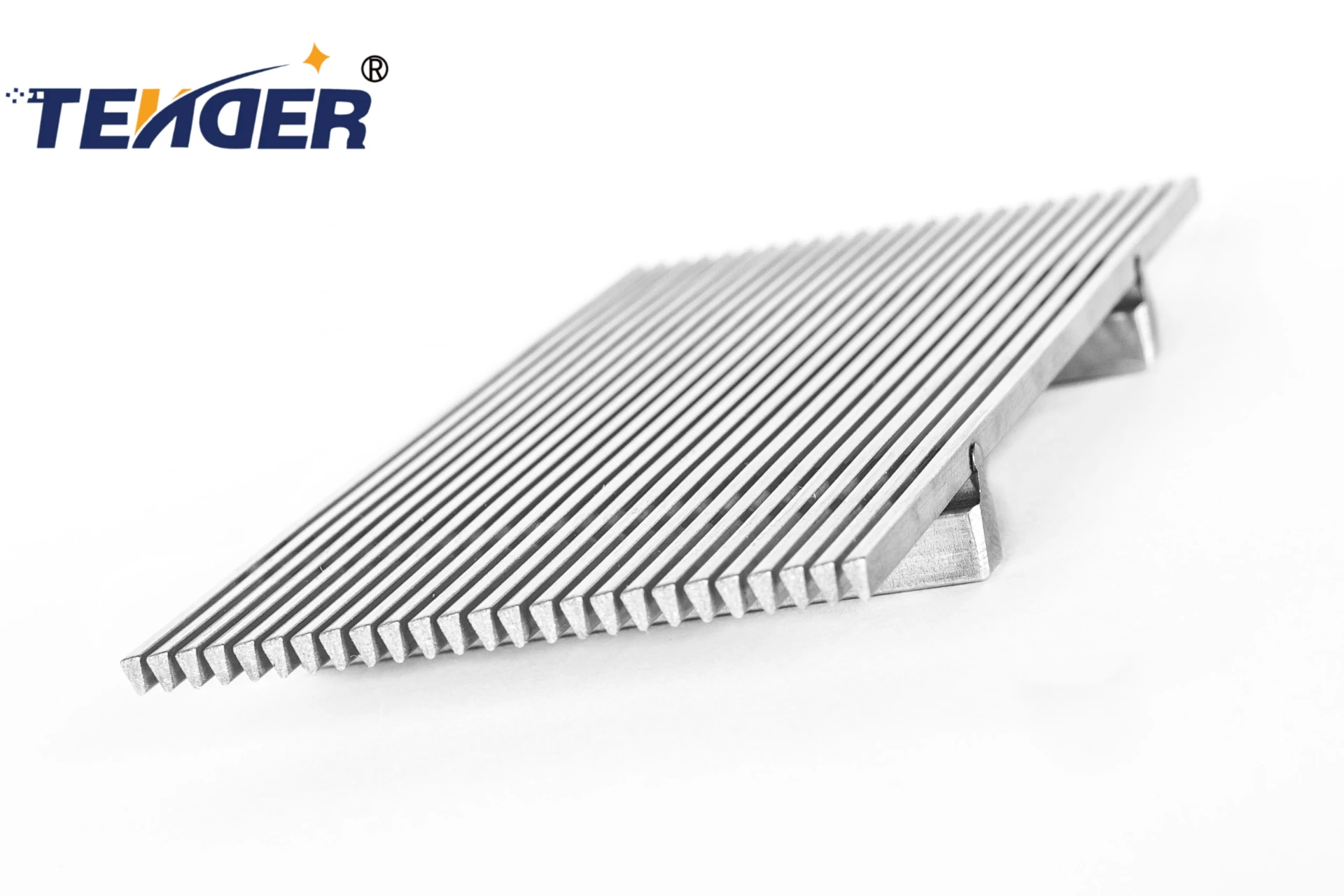

- High mechanical strength: Strong overall rigidity, not easily deformed, resistant to high pressure impact;

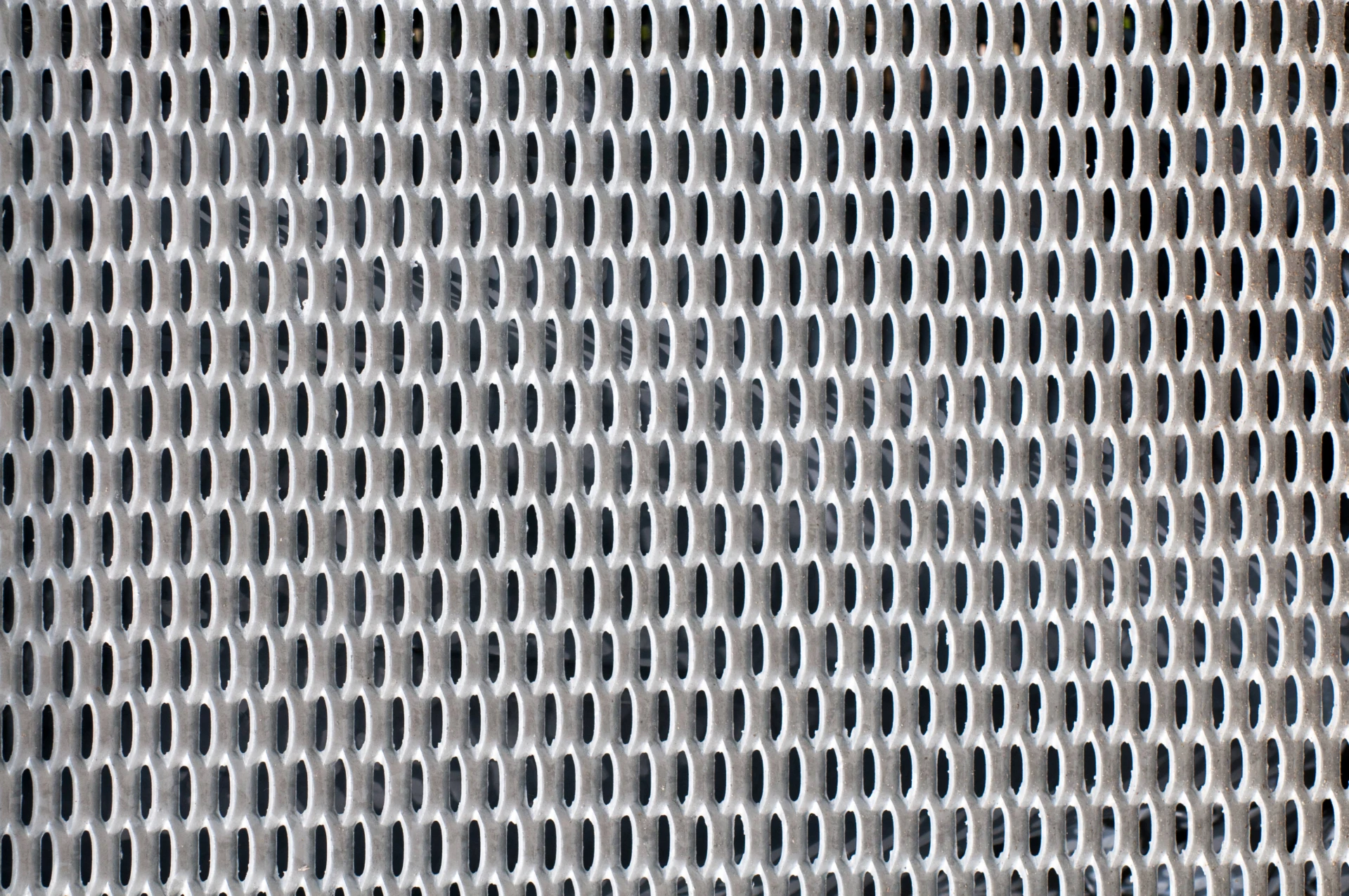

- Stable pore structure: The filtration accuracy is stable and not affected by pressure fluctuations;

- High temperature and corrosion resistance: suitable for high temperature and acid-base corrosion environments;

- Easy to clean and reusable: can be blown back, cleaned with ultrasonic waves, and cleaned chemically;

- Customizable structure and interface: meet diverse industrial needs.

-

Common Specifications

Parameter

Specification Range / Options

Filter Media

Multi-layer sintered stainless steel mesh (typically 5 layers)

Material

SS 304, SS 316L (standard); also available: Monel, Inconel, Hastelloy, Titanium

Number of Layers

5 layers (standard), or 3–7 layers customizable

Outer Diameter (OD)

25 mm – 150 mm (1" – 6")

Length

50 mm – 1200 mm (2" – 48")

Filtration Accuracy

1 μm – 200 μm (typical options: 1, 5, 10, 20, 40, 75, 100, 150 μm)

Pore Size Uniformity

High uniformity, deviation <±10%

Flow Direction

Inside to outside / Outside to inside (customizable)

Working Pressure

Up to 30 MPa (based on wall thickness and support layer)

Working Temperature

-200°C to +600°C (depending on material)

Filter Shape

Cylindrical (standard), conical, disc, capsule, pleated types available

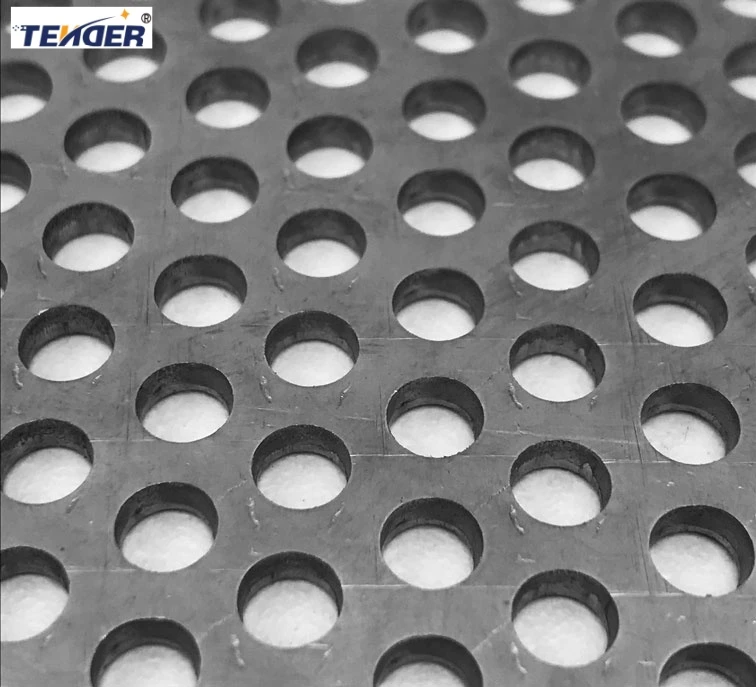

Support Structure

With inner perforated core or support frame

Sealing Methods

Welding (TIG), epoxy bonding, O-ring sealing

End Cap Types

Thread (NPT/BSP), flange, clamp, quick connect, customized

Surface Treatment

Pickling, passivation, polishing

Cleaning Methods

Ultrasonic, backflushing, high-pressure cleaning, acid/alkali soaking

-

Application Area

- Petrochemical industry (filtration of high-temperature and high-pressure reaction systems)

- Pharmaceutical industry (steam, liquid filtration)

- Food and beverages (pre-treatment of beer and dairy products)

- Water treatment (ultrafiltration, reverse osmosis pre filtration)

- Gas purification (compressed air, hydrogen, natural gas)

- Military and aerospace systems

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.