-

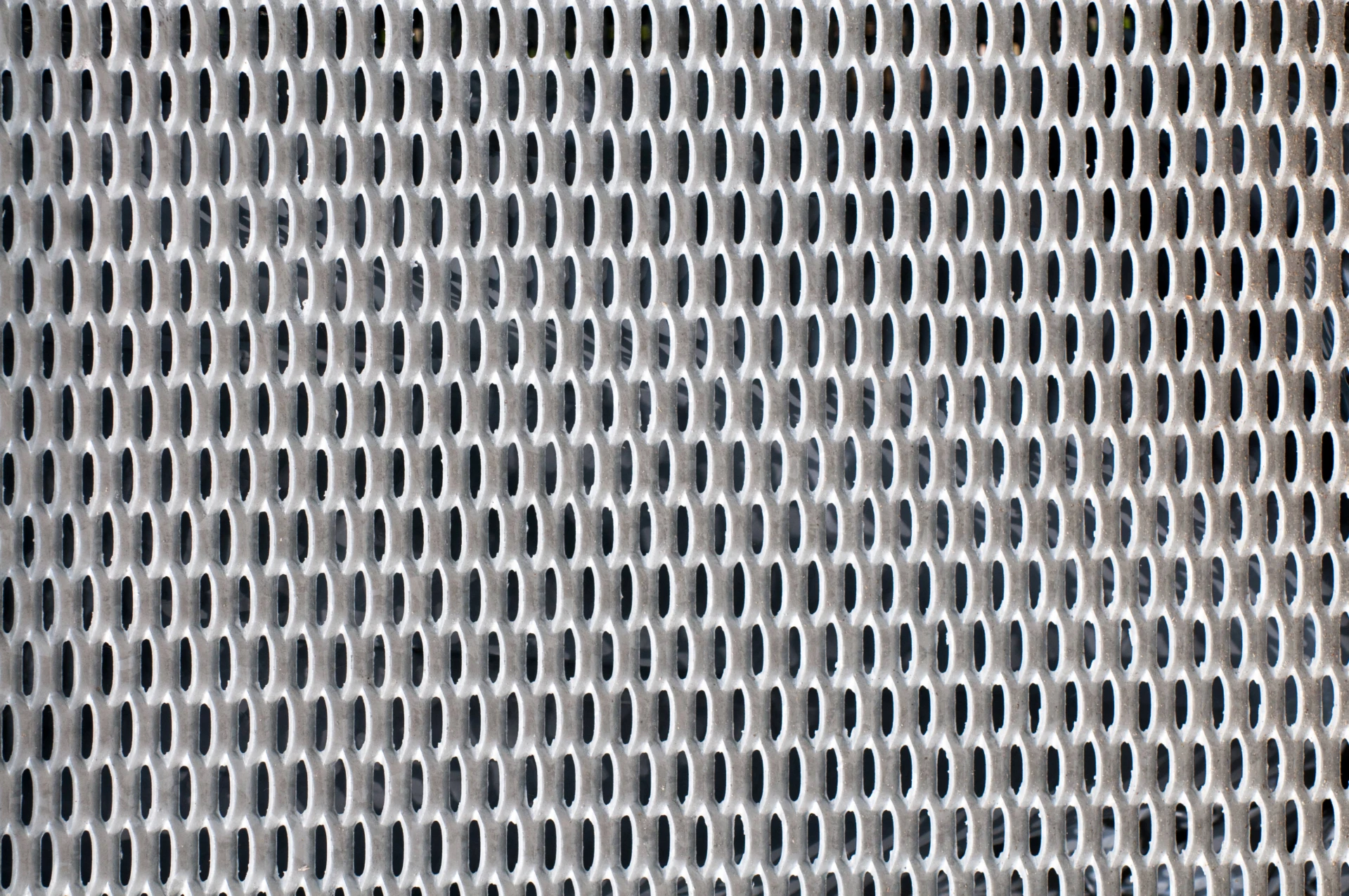

Characteristic Advantages

1.Excellent corrosion resistance

The most notable feature of Hastelloy mesh is its excellent corrosion resistance, particularly suitable for the following environments:

Strong acid environment (such as sulfuric acid, hydrochloric acid, phosphoric acid, acetic acid)

Strong oxidant media (such as chlorine gas, hypochlorite)

Seawater and salt spray environment

Wet chloride environment (such as wet chlorine gas)

2. Excellent high-temperature performance

Hastelloy can maintain structural stability and oxidation resistance at high temperatures.

Suitable for filtration and separation operations in high-temperature atmospheres or corrosive high-temperature liquids.

3. High strength and good mechanical properties

Hastelloy still has good tensile strength and ductility in high temperature and corrosive environments.

Not easy to break and has a long service life.

-

Common Specifications

According to usage, there are four commonly used specifications for Hastelloy alloy:

Hastelloy C-276: Universal type, resistant to various acids and reducing corrosion.

Hastelloy C-22: Has stronger resistance to wet chlorine and various strong oxidants.

Hastelloy B-2: Especially suitable for hydrochloric acid environments.

Hastelloy X: mainly used in high-temperature applications, commonly used in the aviation industry

Specification sheet of Hastelloy B woven wire mesh

Item

Mesh (Wires/ in.)

Wire diameter (in.)

Width of opening (in.)

Open area (%)

RHB-01

16 × 16

0.014

0.049

60.2

RHB-02

30 × 30

0.0085

0.025

55.4

RHB-03

30 × 30

0.0106

0.0227

46.5

RHB-04

60 × 60

0.0072

0.009

30.5

RHB-05

200 × 200

0.002

0.003

36

Specification sheet of Hastelloy C276 woven wire mesh

Item

Mesh (Wires/ in.)

Wire diameter (in.)

Width of opening (in.)

Open area (%)

RHC276-08

16 × 16

0.018

0.045

50.7

RHC276-09

16 × 16

0.009

0.0535

73.27

RHC276-10

20 × 20

0.023

0.027

29.2

RHC276-11

20 × 20

0.016

0.034

46.2

RHC276-12

20 × 20

0.009

0.041

67.2

RHC276-13

24 × 24

0.014

0.028

44.2

RHC276-14

30 × 30

0.013

0.02

37.1

RHC276-15

30 × 30

0.009

0.024

53.1

RHC276-16

40 × 40

0.01

0.015

36

RHC276-17

40 × 40

0.009

0.016

41

RHC276-18

40 × 40

0.0075

0.018

49

RHC276-19

50 × 50

0.009

0.011

30.3

RHC276-20

60 × 60

0.0072

0.009

30.5

RHC276-21

60 × 60

0.0044

0.0123

54.2

RHC276-22

80 × 80

0.007

0.006

19.4

RHC276-23

80 × 80

0.001

0.0085

46.2

RHC276-24

100 × 100

0.001

0.006

36

RHC276-25

120 × 120 T

0.004

0.0043

27

RHC276-26

180 × 180

0.002

0.0036

41

RHC276-27

200 × 200

0.0023

0.0027

48

RHC276-28

200 × 200

0.002

0.003

36

Specification sheet of Hastelloy X woven wire mesh

Item

Mesh (Wires/ in.)

Wire diameter (in.)

Width of opening (in.)

Open area (%)

RHX-01

10 × 10

0.025

0.075

56.3

RHX-02

18 × 18

0.009

0.047

70.4

RHX-03

20 × 20

0.016

0.034

46.2

RHX-04

50 × 50

0.003

0.017

72.3

RHX-05

60 × 60

0.0075

0.009

30.5

-

Application area

Common applications include:

Chemical equipment filter mesh, catalyst carrier

Heat exchanger mesh

Pickling equipment rack

Aviation Gas System Filter Components

Metal screen mesh for offshore platforms

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.