-

Characteristic Advantages

- Extremely high temperature resistance and sustainable operation in high temperature environments above 1100 ° C~1350 ° C

- Good oxidation resistance. High aluminum content will form a stable Al ₂ O ∝ oxide film at high temperatures, protecting the metal body

- High resistivity is suitable for heating elements, electric heating tubes, and other applications

- Good corrosion resistance, especially suitable for oxidizing or sulfurizing atmospheres

- Light weight, high strength. Compared with stainless steel, the unit weight is lighter and the flexibility is better

-

Common Specifications

Grade Name

Standard Equivalent

Main Chemical Composition (wt%)

Key Features

Continuous Operating Temp.

Typical Applications

0Cr21Al6Nb

Chinese GB Standard

Cr 20.5–21.5%, Al 5.5–6.5%, Nb ≤0.6%, Fe balance

Dense oxide layer, excellent high-temp oxidation resistance, high strength

~1250°C

Electric furnace wire, heating mesh, IR heaters

0Cr27Al7Mo2

Chinese GB Standard

Cr 26–28%, Al 6–8%, Mo 1.8–2.2%, Fe balance

Enhanced corrosion & sulfur resistance, ideal for harsh atmospheres

~1350°C

Sulfuric gas heating, chemical furnaces

FeCrAl 135 / Kanthal A-1

International Standard

Cr ~22%, Al ~5.8%, Fe balance

Globally recognized, excellent stability, long service life

~1400°C

Industrial heaters, heat treatment, resistance mesh

Kanthal D

Sandvik Kanthal Series

Cr ~23%, Al ~5%, Mo trace, Fe base

High formability, suitable for complex shapes and sintered structures

~1300°C

Electric heating belts, heating tubes, mesh cylinders

Resistohm 145

Isabellenhütte (France)

Cr ~22%, Al ~5.5%, Fe balance

Similar to A-1 with improved electrical resistance stability

~1350°C

Precision resistors, electric thermal control

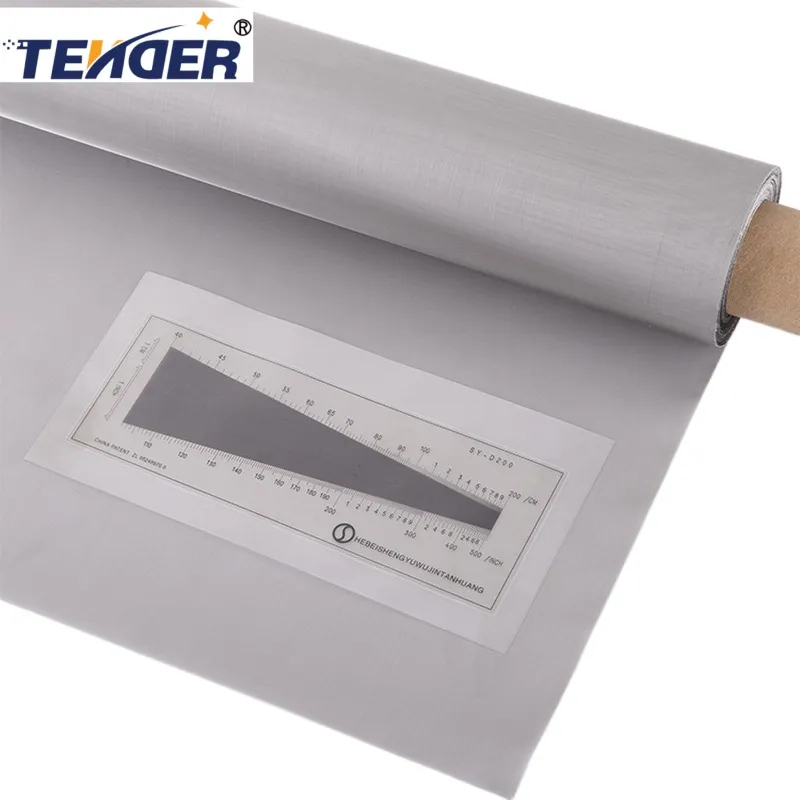

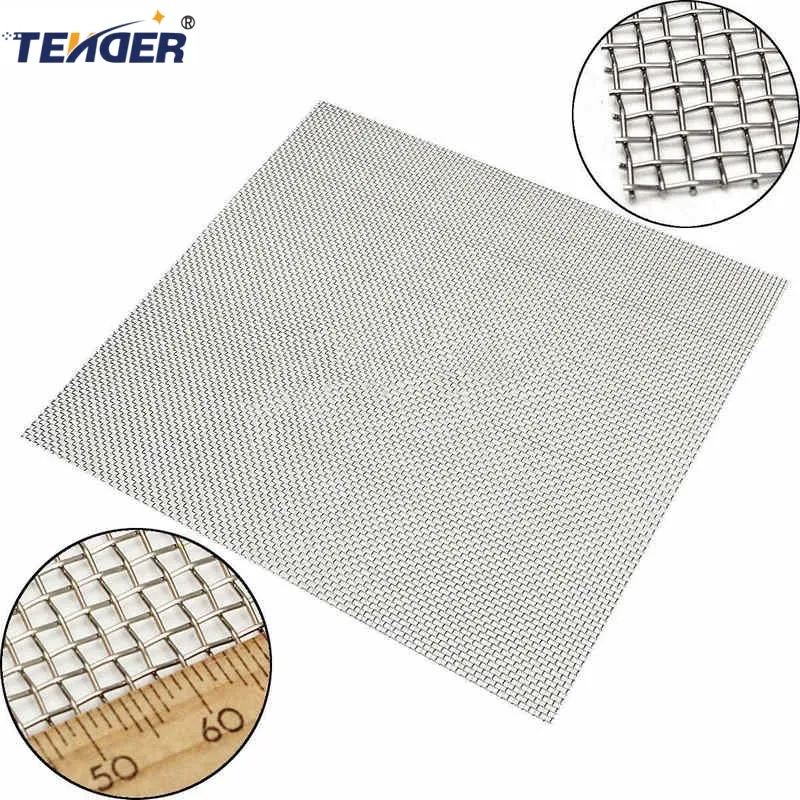

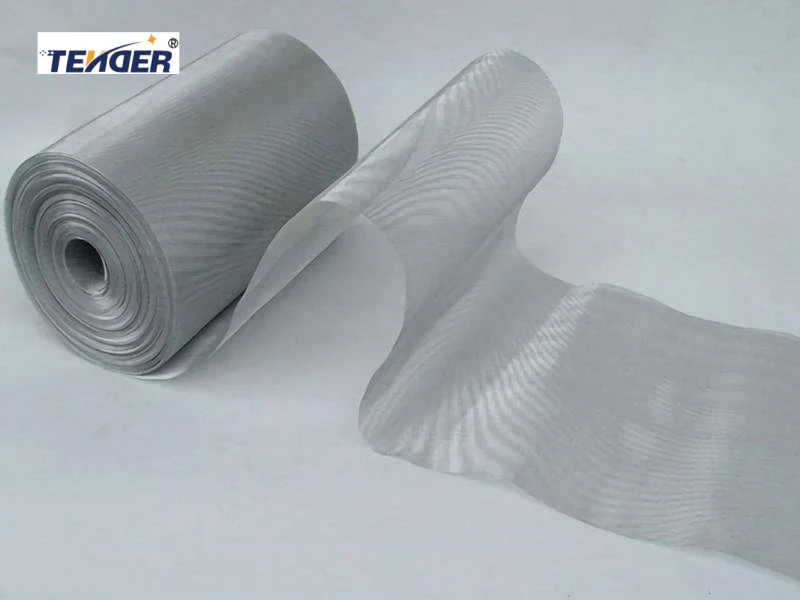

Mesh Count

Wire Diameter (mm/inch)

Aperture (mm/inch)

Open Area (%)

Weave Type

Weight (kg/m²)

Typical Application

4 × 4

0.8 mm / 0.0315"

5.55 mm / 0.218"

~76%

Plain weave

~2.6

Sintering support, hot air mesh

6 × 6

0.6 mm / 0.0236"

3.63 mm / 0.143"

~70%

Plain weave

~2.2

Heating frames, fluidized beds

10 × 10

0.5 mm / 0.0197"

2.04 mm / 0.080"

~65%

Plain weave

~2.0

Catalyst support, heating mesh

14 × 14

0.4 mm / 0.0157"

1.41 mm / 0.055"

~60%

Plain weave

~1.7

Hot air circulation

20 × 20

0.35 mm / 0.0138"

0.92 mm / 0.036"

~51%

Plain / Twill weave

~1.4

Heating mesh covers

30 × 30

0.25 mm / 0.0098"

0.59 mm / 0.023"

~46%

Twill weave

~1.1

High-temp particle filtration

40 × 40

0.20 mm / 0.0079"

0.43 mm / 0.0169"

~44%

Twill weave

~0.9

Gas distribution

60 × 60

0.15 mm / 0.0059"

0.27 mm / 0.0106"

~40%

Twill / Dutch weave

~0.7

Catalyst base mesh

80 × 80

0.12 mm / 0.0047"

0.20 mm / 0.0079"

~36%

Dutch weave

~0.6

High-temp dust/oil filtration

120 × 120

0.07 mm / 0.0028"

0.144 mm / 0.0057"

~30%

Dutch / Rev. Dutch

~0.45

Fine heating panels, filters

160 × 800

0.07 / 0.04 mm

Dense (not visible)

<10%

Reverse Dutch weave

~0.4

Battery supports, sintered mesh

-

Application Area

Industrial electric furnace heating element

Distributed heating network

Catalytic converter carrier support mesh

Gas diffusion, battery electrodes

High temperature filter screen

Automotive exhaust purification and filtration support layer

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.