-

Characteristic advantages

- Ultra high melting point and thermal stability

The melting point of molybdenum is as high as 2620 ° C, and it can work stably for a long time in extremely high temperature environments.

Strong thermal shock resistance, not easily cracked or deformed due to sudden temperature changes.

- Excellent corrosion resistance

Has good stability in neutral, weak acid, and weak base solutions.

Especially resistant to oxidation, nitridation, and hydrogen gas atmosphere corrosion under high temperature.

- Good electrical and thermal conductivity

The conductivity is close to that of copper metal, suitable for electric heating or electric field shielding purposes.

Good thermal conductivity and high heat dissipation efficiency.

- High strength and good ductility

Can maintain strength even at high temperatures.

-

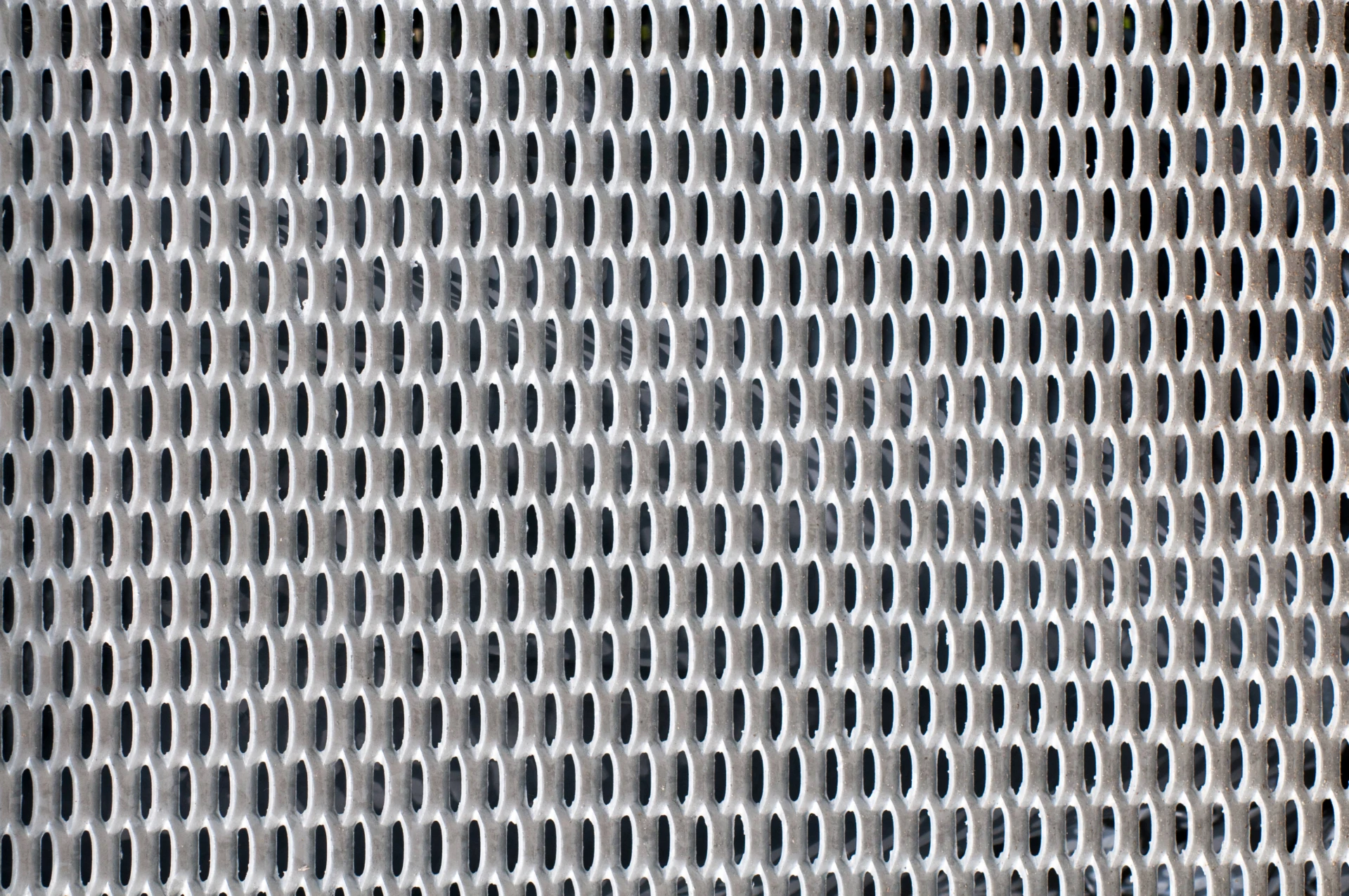

Common specifications

Mesh Count

Aperture Size (mm)

Typical Wire Diameter (mm)

Application Reference

10 mesh

2

0.5

Coarse filtration, heating support mesh

20 mesh

1

0.4

Furnace shielding, material loading trays

40 mesh

0.45

0.25

High-temp gas filtration, shielding mesh

60 mesh

0.3

0.2

Sintering support mesh, filter layers

80 mesh

0.2

0.15

Vacuum evaporation, fine filtration

100 mesh

0.15

0.12

Semiconductor gas distribution systems

150 mesh

0.1

0.08

Micron filtration, electronic shieldin

Item

Range

Standard Widths

10 mm – 1500 mm (customizable)

Standard Lengths

Usually 30 meters per roll, or cut as required

Material Purity

≥ 99.95% Mo

Type

Features

As-woven Moly Mesh

Dark gray or silvery metallic surface

Vacuum Annealed Mesh

Improved ductility, reduced internal stress, suitable for high-temp use

Custom Shapes

Can be cut into discs, strips, or other required forms

-

Application Area

1 . Vacuum furnaces and molybdenum boats are used as heating elements, insulation screens, or material support devices for high-temperature furnaces

2 . Semiconductor industry is used for electron beam evaporation, ion implantation, high-temperature support, etc

- Used in the metallurgical industry as high-temperature filtration materials and sintering support nets

4 Aerospace applications for high-temperature structural components and combustion chamber shielding nets

Processing quartz glass as a support, heating or sintering carrier

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.