-

Characteristic advantages

Good corrosion resistance (suitable for freshwater and air environments)

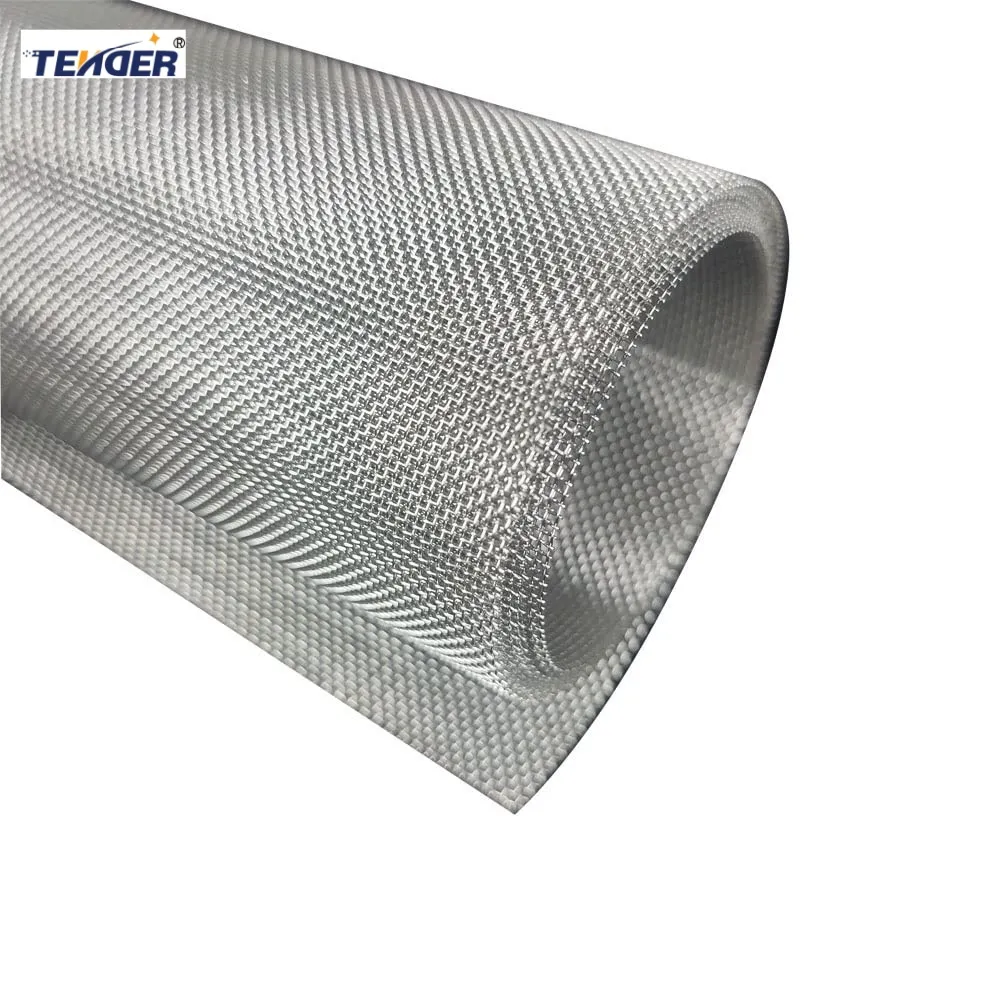

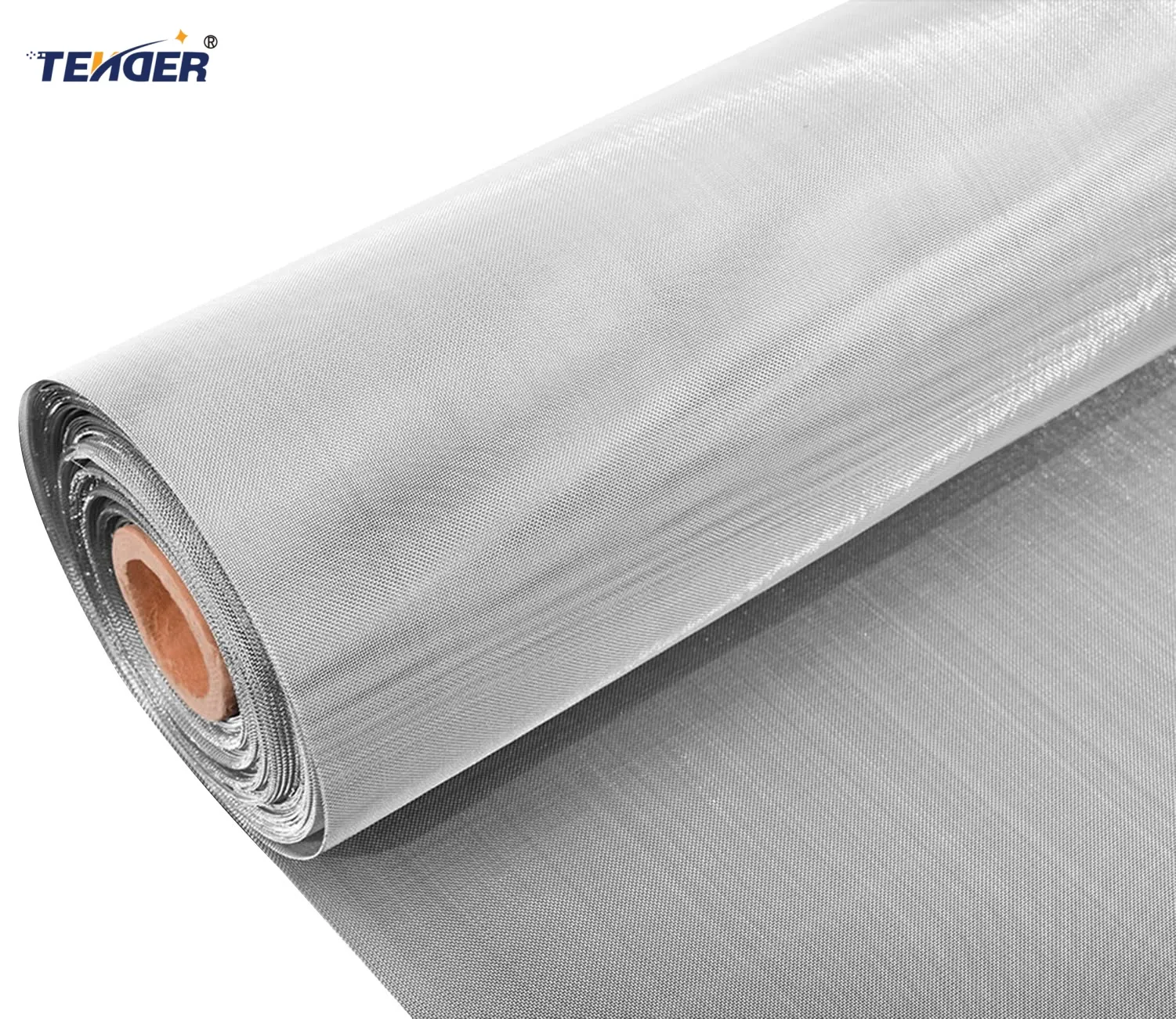

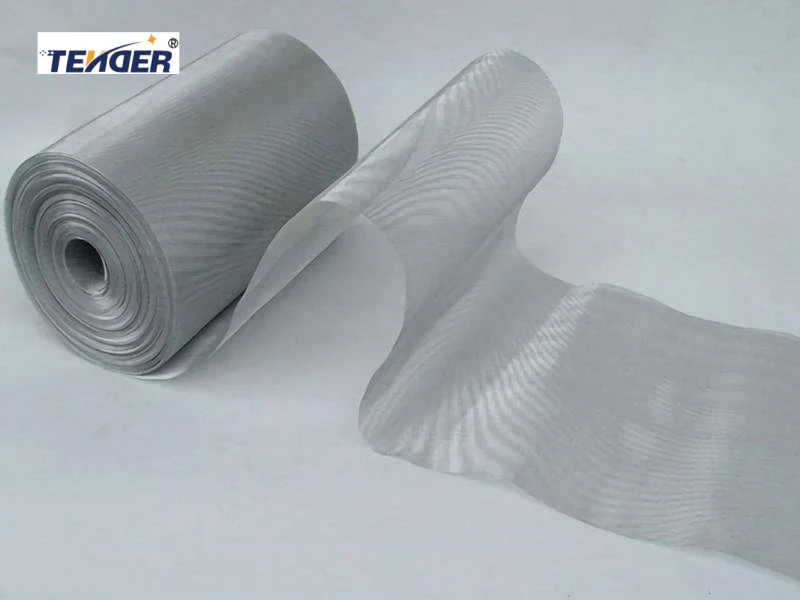

Excellent ductility and processability

High conductivity

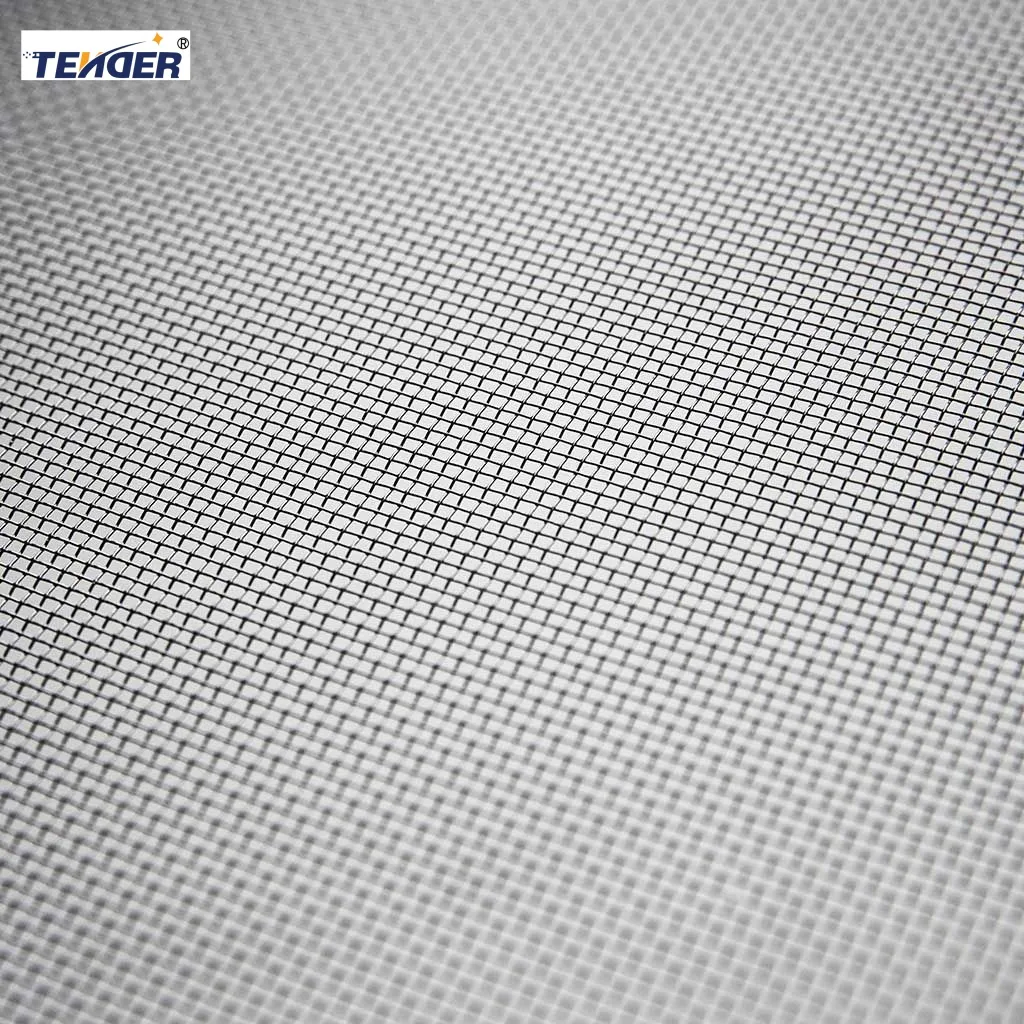

Smooth mesh surface, golden color, beautiful and generous

Non-magnetism Material

-

Common specifications

Material: stainless steel wire 304, 304L, 316, 316L, 310, 314, 410, 430.

Weaving type: plain weave, twill weave, dutch twill.

Serial Number

Mesh Count

Wire Diameter

Mesh Hole Size

Thickness

Maximum Width

Opening rate

Inches

mm

Inches

mm

mm

mm

%

SS-1

1 × 1

0.157

4

0.84

21.4

8

2000

71

SS-2

2 × 2

0.118

2.5

0.38

10.2

5

2000

64.5

SS-3

3 × 3

0.079

2

0.25

6.4

4

2000

58

SS-4

4 × 4

0.063

1.6

0.187

4.75

3.2

2000

56

SS-5

4 × 4

0.047

1.2

0.203

5.15

2.4

2000

65.8

SS-6

5 × 5

0.055

1.4

0.14

3.68

2.8

2000

52.5

SS-7

6 × 6

0.047

1.2

0.12

3.03

2.4

2000

51.3

SS-8

8 × 8

0.43

1.1

0.08

2.08

2.2

2000

42.8

SS-9

10 × 10

0.039

1

0.06

1.54

2

2000

36.8

SS-10

10 × 10

0.02

0.51

0.08

2.03

1.02

2000

63.9

SS-11

12 × 12

0.023

0.584

0.06

1.52

1.17

2000

52.2

SS-12

12 × 12

0.02

0.508

0.063

1.6

1.02

2000

57.6

SS-13

14 × 14

0.023

0.584

0.048

1.22

1.17

2000

45.7

SS-14

14 × 14

0.02

0.508

0.051

1.3

1.02

2000

51.7

SS-15

16 × 16

0.018

0.457

0.0445

1.13

0.91

2000

50.7

SS-16

18 × 18

0.017

0.432

0.0386

0.98

0.86

2000

48.2

SS-17

20 × 20

0.02

0.508

0.03

0.76

1.02

2000

35.9

SS-18

20 × 20

0.016

0.406

0.034

0.86

0.81

2000

46.1

SS-19

24 × 24

0.014

0.356

0.0277

0.7

0.71

2000

43.9

SS-20

30 × 30

0.013

0.33

0.0203

0.52

0.66

2000

37.4

SS-21

30 × 30

0.012

0.305

0.0213

0.54

0.61

2000

40.8

SS-22

30 × 30

0.009

0.229

0.0243

0.62

0.46

2000

53.3

SS-23

35 × 35

0.011

0.279

0.0176

0.45

0.56

2000

38.1

SS-24

40 × 40

0.01

0.254

0.015

0.38

0.51

2000

35.9

SS-25

50 × 50

0.009

0.229

0.011

0.28

0.46

2000

30.3

SS-26

50 × 50

0.008

0.203

0.012

0.31

0.41

2000

36.5

SS-27

60 × 60

0.0075

0.191

0.0092

0.23

0.38

2000

29.8

SS-28

60 × 60

0.007

0.178

0.0097

0.25

0.36

2000

34.1

SS-29

70 × 70

0.0065

0.165

0.0078

0.2

0.33

2000

30

SS-30

80 × 80

0.0055

0.14

0.007

0.18

0.28

2000

31.6

SS-31

80 × 80

0.0047

0.12

0.0077

0.197

0.24

2000

38.6

SS-32

90 × 90

0.005

0.127

0.0061

0.16

0.25

2000

31.1

SS-33

100 × 100

0.0045

0.114

0.0055

0.14

0.23

2000

30.4

SS-34

100 × 100

0.004

0.102

0.006

0.15

0.2

2000

35.4

SS-35

100 × 100

0.0035

0.089

0.0065

0.17

0.18

2000

43.1

SS-36

110 × 110

0.004

0.1016

0.0051

0.1295

0.2

2000

31.4

SS-37

120 × 120

0.0037

0.094

0.0046

0.1168

0.19

2000

30.7

SS-38

150 × 150

0.0026

0.06

0.0041

0.1041

0.12

2000

40.2

SS-39

160 × 160

0.0025

0.0635

0.0038

0.0965

0.13

2000

36.4

SS-40

180 × 180

0.0023

0.0584

0.0033

0.0838

0.12

2000

34.7

SS-41

200 × 200

0.0021

0.0533

0.0029

0.0737

0.11

2000

33.7

SS-42

250 × 250

0.0016

0.04

0.0024

0.061

0.08

2000

36.5

SS-43

270 × 270

0.0016

0.04

0.0021

0.054

0.08

2000

33

SS-44

300 × 300

0.0016

0.04

0.0018

0.0446

0.08

2000

27.8

SS-45

325 × 325

0.0014

0.0356

0.0017

0.0432

0.07

2000

30.1

SS-46

400 × 400

0.0011

0.03

0.0015

0.033

0.06

1600

27.4

SS-47

500 × 500

0.001

0.0254

0.001

0.0254

0.05

1500

25

SS-48

635 × 635

0.0008

0.0203

0.0008

0.0203

0.04

1300

25

-

Application area

- Industrial filtration

Liquid, gas, and slurry filtration in industries such as petroleum, chemical, and metallurgical

- Architecture and Decoration

Curtain wall decoration net, elevator decoration net, ceiling, wall decoration

- Food processing

Food grade sieve, drying rack, barbecue mesh, conveyor belt

- Mining and screening

Screening and grading of sand, ore, coal, aggregates, etc

- Electronic and electromagnetic shielding

Electromagnetic wave shielding and electrostatic conductivity in precision electronic devices

- Aerospace and Military Industry

High precision filtration in aviation fuel systems and hydraulic systems

- Agriculture and Environmental Protection

Horticultural pest control net, livestock breeding net, aquaculture net

- Laboratory and Pharmaceutical Industry

Experimental filtration, powder screening, and cleaning basket

application area

Recommended materials

Common mesh range

Industrial filtration

304, 316L

10–200 mesh

Architectural decoration

304, 316

10–80 mesh

food processing

304

10–50 mesh

Ore screening

201, 304

1–30 mesh

Laboratory/Pharmaceutical

316L

80–400 mesh

-

What is the average lead time?

Request a Quote

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.